General description of torsionally flexible jaw couplings

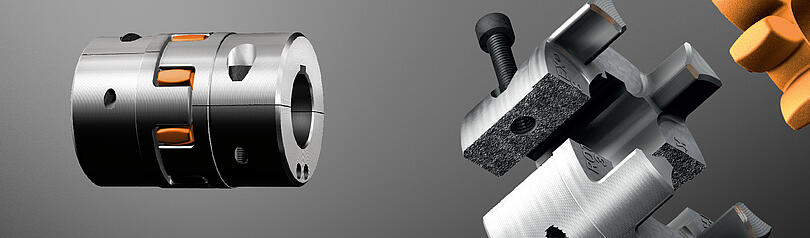

ROTEX® torsionally flexible jaw couplings are elastomer couplings characterized by a compact design.

In spite of low weights and mass moments of inertia of the elastomer couplings they are able to transmit high torques. The compact shaft couplings are characterized by a long service life and sound operating characteristics generated by allover machining.

Thanks to the elastomer (elastomer spider) between the coupling hubs of the jaw couplings shocks respectively torsional vibrations in the drive train are damped. The high temperature-resistant spider material T-PUR® (elastomer) is available in various degrees of hardness. The torsionally flexible ROTEX couplings are used in almost every range of general machinery and plant engineering.

Properties of torsionally flexible jaw couplings:

ROTEX shaft couplings consist of two hubs (aluminium or steel) and a spider (elastomer ring / cam ring) made of T-PUR® (elastomer). The different degrees of hardness of the T-PUR-spider allow to adjust the level of damping and torsional stiffness of the elastomer coupling.

ROTEX couplings require few mounting space and thus enable easy assembly/disassembly. The numerous types provide for maximum flexibility and meet with the different mounting requirements through various types of hubs.

Function of torsionally flexible jaw couplings:

Jaw couplings ensure torsional vibration-damping power transmission and absorb shocks generated by machines with irregular operation.

In contrast to flexible couplings the connecting elements of which are subjected to bending and therefore to earlier wear, the flexible teeth of ROTEX couplings (elastomers) are subjected to compressive stress only. The benefit of the elastomer coupling thus is to resist significantly higher loads.

The elastomers become deformed with load and high speeds. Sufficient expansion space must be provided.

All sizes of ROTEX elastomer couplings have a maximum torsion angle of 5°. They can be mounted both horizontally and vertically.

Material of torsionally flexible jaw couplings:

Our elastomer material T-PUR® (elastomer) is resistant to higher temperatures and has a considerably longer service life than common polyurethanes. From a visual point of view we marked the T-Pur material by the colours orange (92 Shore A), purple (98 Shore A) and light green (64 Shore D).

The previous polyurethane spiders in the colours yellow, red and natural white with green marking of teeth continue to be available on request.