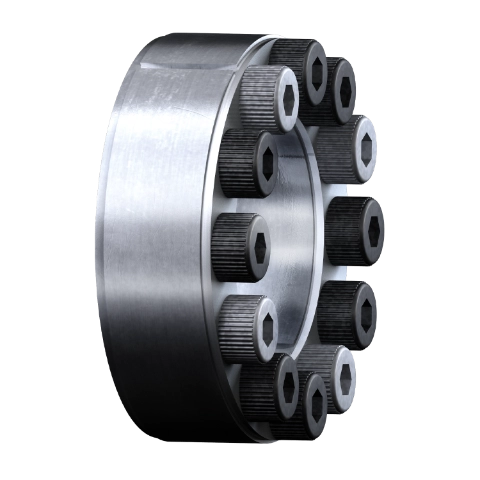

The not self-centering CLAMPEX® KTR 100 clamping set is a backlash-free shaft-hub-connection.

Compared to other clamping sets a larger shaft and hub tolerance is permissible with CLAMPEX KTR 100. The use of the CLAMPEX KTR 100 claming element requires direct centering between shaft and hub.

The internal clamping set is suitable for large shaft and hub tolerances.

Features

backlash-free shaft-hub-connection

simultaneous transmission of torque and axial force

suitable for large shaft and hub tolerances

operating temperature from -20 °C to +160 °C

no axial displacement of hub to shaft during assembly

Product Details

Specifications for: CLAMPEX® KTR 100

Further information and specifications can be found in our online catalogue.