Machine tools: High dynamics and accurate positioning

Higher cutting performance, rising spindle speeds and higher precision: these are the essential trends in machine tool industry. For many manufacturers the focus of development is on rising speeds. Apart from that digitization has got strong impacts: latest generations of machinery record and process large data volume and can be integrated in superordinate IT systems to a great extent.

At the same time there is increasing competitive pressure in the core segments caused by new technologies (keyword: additive manufacturing). Another influential factor is the future development of automotive industry: now as before a significant share of machine tools in the field is used for the production of I. C.-engines.

Couplings for machine tools

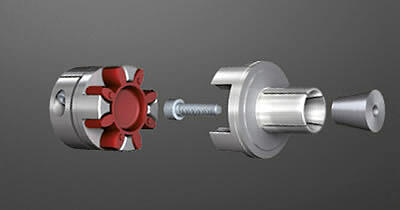

In 1980 we introduced the backlash-free and torsionally flexible jaw coupling ROTEX GS to the sophisticated industry. In 1994 the coupling system ROTEX GS P developed by KTR was included in the standard for stub spindles DIN 69002. In addition the product portfolio comprises the backlash-free and torsionally rigid coupling types RADEX-NC with steel lamina and TOOLFLEX with metal bellow. To comply with the high demands on positioning drives and the drive of main spindles, we develop our range of couplings continuously. Part of the current innovations is ROTEX GS HP. This trendsetting development is suitable for such high speeds that the market for such couplings yet has to be established.

Clamping elements for machine tools

Our external clamping sets CLAMPEX allow for a backlash-free and non-positive shaft-hub-connection. Clamping is made via integrated screws used for non-destructive releasing of clamping elements for machine tools. Subject to their benefits CLAMPEX clamping elements are inter alia preferred as an alternative to feather key connections.

Our product range for Machine Tools

EVOLASTIC® E/EP

Individual elastomer version for a wide range of applications.

Find the right product quickly and easily with the KTR product finder

Product finder

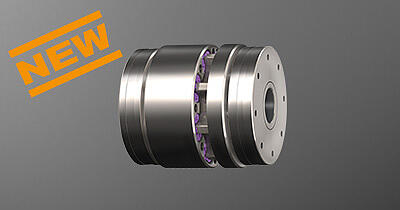

ROTEX® GS HP

Very high speeds, for example main spindle drives and test benches

TOOLFLEX® Mini

Miniature bellow-type coupling - backlash-free and easy to assemble

ROTEX® GS ZR2

Cardan shaft, intermediate pipe made of steel variable in length

KTR-SI Compact with backlash-free ROTEX® GS

Load-separating safety coupling with backlash-free ROTEX® GS

SYNTEX®-NC with TOOLFLEX

Safety clutch with torsionally rigid metal bellows clutch

CLAMPEX® KTR 225

Combines internal diameter of hub with various shaft diameters

CLAMPEX® KTR 400

Self-centering clamping element with utmost performance data

ROTEX® GS ZR3

Cardan shaft, intermediate pipe made of aluminium variable in length

Rigid shaft couplings CLAMPEX KTR 700

Rigid shaft couplings for backlash-free, bending and torsionally stiff shaft-to-shaft connection. Among others, CLAMPEX®