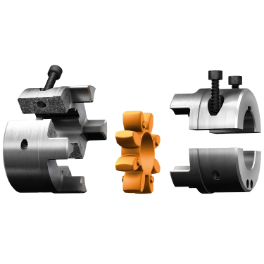

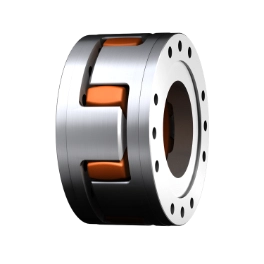

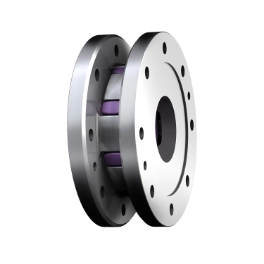

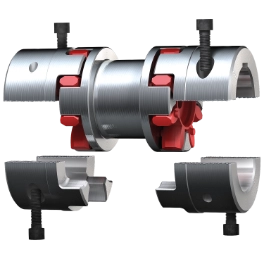

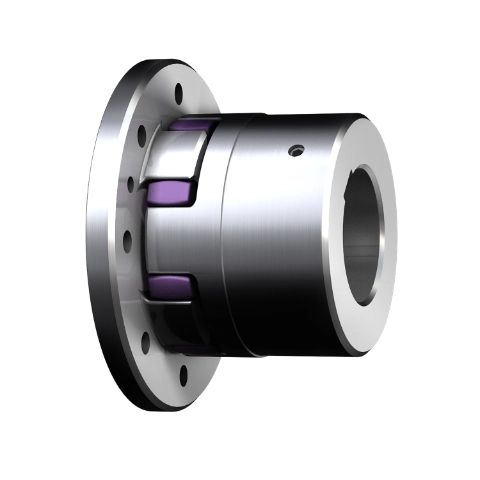

The torsionally flexible jaw coupling ROTEX® CF is an elastomer coupling with a flange connection on one side (flange coupling) and particularly suitable for heavy engineering.

Type CF of the ROTEX elastomer coupling is characterized by a short mounting length of the flange connection on one side.

The driving flanges and hubs are available from stock. The flange is available from stock both with tapped hole and without hole/without centering.

Features

torsionally flexible jaw coupling as a flange type for heavy engineering

driving flanges and hubs available from stock

flange with tapped holes available from stock

flange without bore and without centering available from stock

material: driving flange 3b made of GGG40 (nodular iron)

Product Details

Specifications for: ROTEX® CF

Further information and specifications can be found in our online catalogue.

CAD drawings

Find 2D CAD drawings for download here.

You need 3D drawings instead? Then please visit our 3D CAD library.