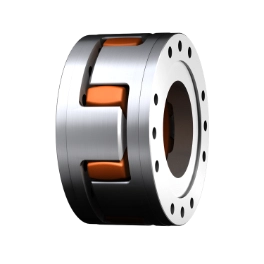

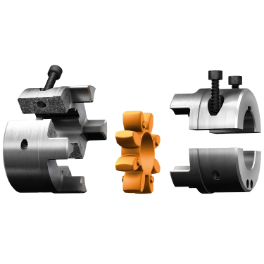

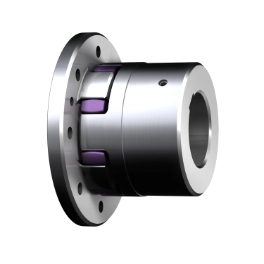

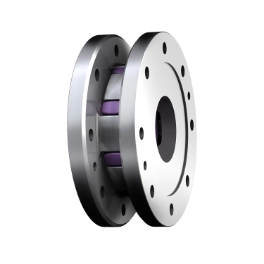

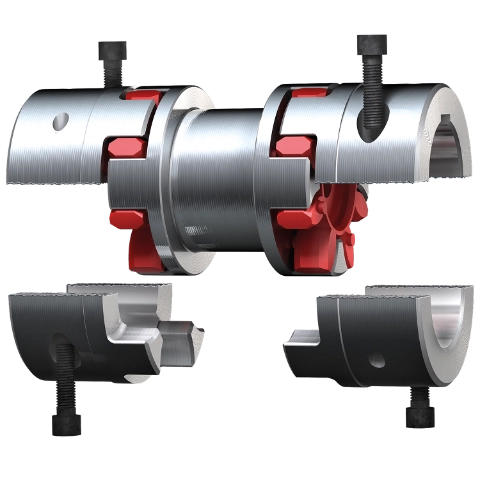

The torsionally flexible jaw coupling ZS-DKM-SH is a double-cardanic elastomer coupling with split hubs (SH SPLIT).

The ROTEX ZS-DKM-SH with SPLIT hub provides the advantage that the coupling can be radially assembled and disassembled without displacing the adjacent power packs. The hub resp. connection of the two hub halves is not weakened by cracking.

This design is also referred to as drop-our center design coupling, half shell coupling, clamping coupling, coupling with split hubs or elastomer coupling with split clamping hub.

The hubs of the double-cardanic jaw coupling ROTEX ZS-DKM-SH are mechanically split by cracking and screwed back together with the assembly. This elastomer coupling is ideally suitable to offset larger radial displacements. Due to the split hubs the coupling can be radially assembled and disassembled without displacing the adjacent power packs.

Features

double-cardanic jaw coupling for large shaft displacements

good damping properties due to double arrangement of spiders

spacers adapted to drop-out center length of standard pumps

for bigger radial displacements generated by thermal expansion

assembly/disassembly via four screws

Product Details

Specifications for: ROTEX® ZS-DKM-SH

Further information and specifications can be found in our online catalogue.

CAD drawings

Find 2D CAD drawings for download here.

You need 3D drawings instead? Then please visit our 3D CAD library.