Function of a failsafe shaft coupling:

The ROFLEX shaft coupling is composed of two hubs the cams of which are inserted in the tailor-made clearance of the other hub half each.

This short design of the shaft coupling allows to combine shafts having a particularly short shaft distance dimension. The elastomer located between the cams transmits the torques while compensating for any kind of displacement.

Component variance of a failsafe shaft coupling:

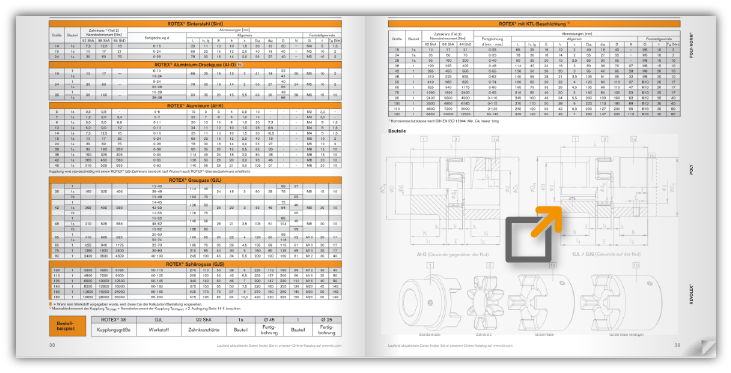

High adaptability with small variance by an optimally graded construction kit system: The elements of the ROFLEX® shaft coupling of one size can be combined with each other without any problem. As a consequence various shaft distances can be generated by the same basic component.

Assembly and service ROFLEX

ROFLEX® SH Split torsionally flexible, failsafe shaft coupling - Assembly and service | KTR Systems