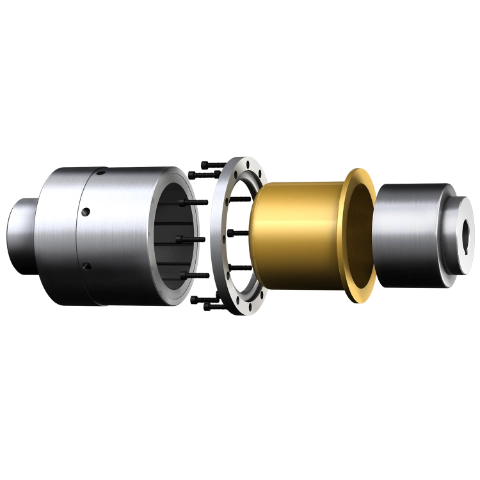

MINEX®-S Magnetic coupling with containment shroud made of ceramics

14 - 600 Nm / Magnetic coupling with containment shroud made of ceramics

Like with the PEEK version, the MINEX magnetic coupling with containment shroud made of ceramics is an economic, energy-efficient alternative to metallic containment shroud version. It does not generate any losses of eddy current and thus does not generate any heat so that usually expensive cooling measures can be eliminated.

Moreover, compared to PEEK the containment shrouds made of ceramics of this magnetic coupling are characterized by higher pressure resistance and excellent temperature resistance.

Features

Magnetic coupling with containment shroud made of ceramics

no generation of heat in the coupling caused by the containment shroud

optimally suitable for specifications of up to 25 bars and +300 °C

torque range from 25 to 550 Nm

internal cooling measures not required

Product Details

Specifications for: MINEX®-S Magnetic coupling with containment shroud made of ceramics

Further information and specifications can be found in our online catalogue.