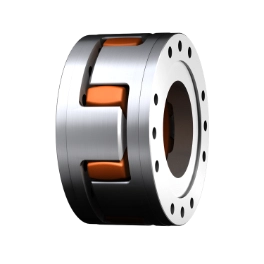

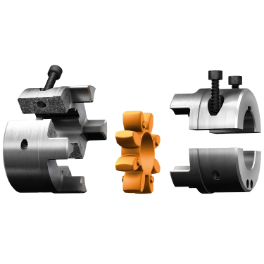

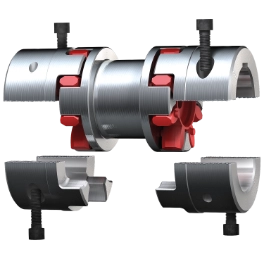

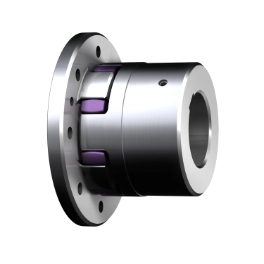

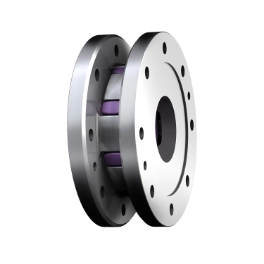

Jaw coupling with clamping ring hubs for fricitionally engaged shaft-hub-connections

ROTEX clamping ring hubs are torsionally flexible elastomer couplings with an integrated clamping system for frictionally engaged shaft-hub-connections.

Thanks to the integrated clamping system the ROTEX clamping ring hubs are able to transmit high friction torques. The internal clamping screws allow for easy assembly of the coupling.

Due to the rotation symmetry this type is additionally characterized by particularly smooth running

Features

torsionally flexible jaw couplings with integrated clamping system

friction connection for cylindrical shafts

application up to a circumferential speed of 40 m/s

particularly smooth running

high friction torques

Product Details

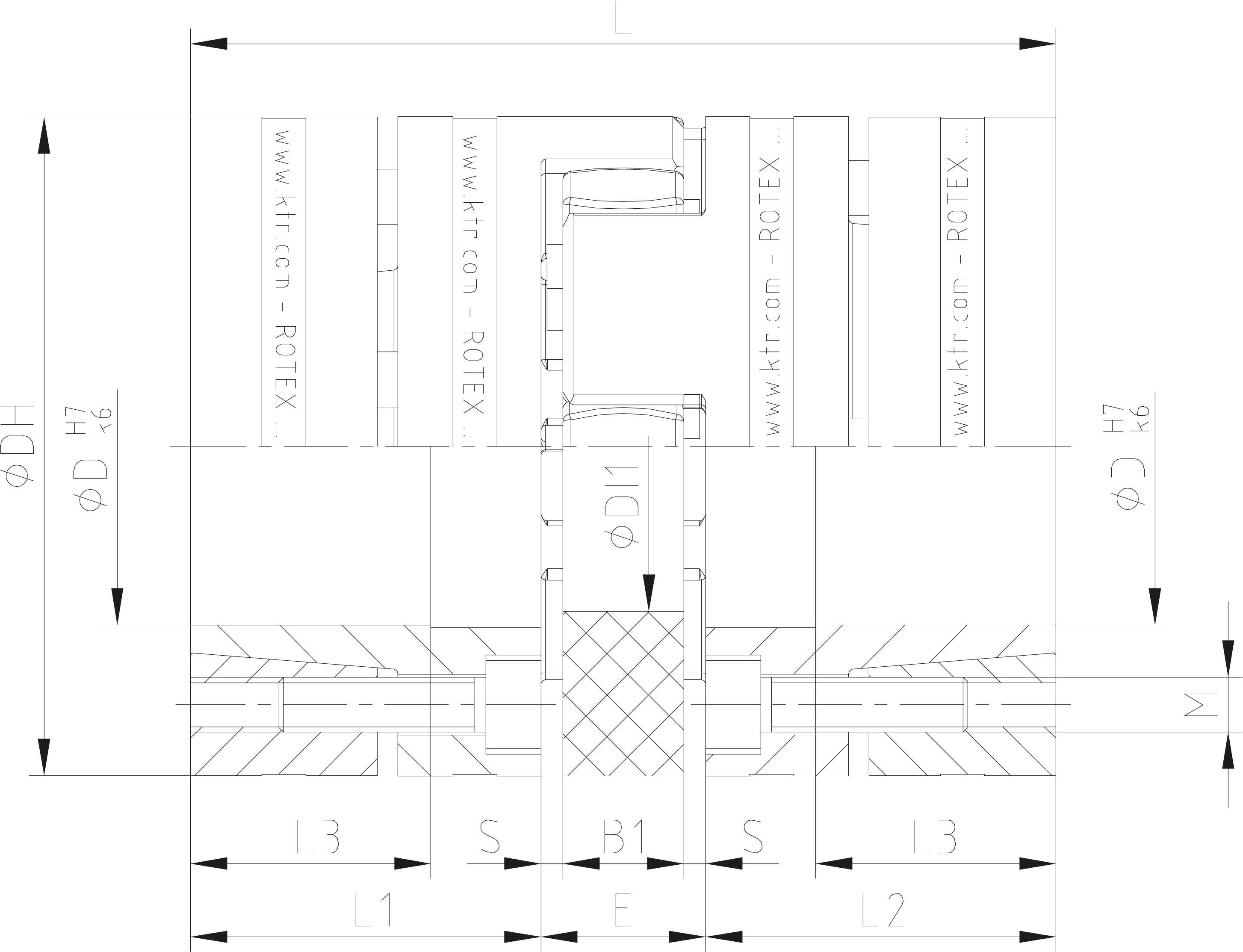

| Size | Spider (component 2) Rated torque [Nm] | Dimensions [mm] | Clamping screws DIN EN ISO 4762 | Weight per hub with max.bore [kg] | Mass moment of inertia per hub with max. bore [kgm²] | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 92 ShA | 98 ShA | 64 ShD | D max. | DH | DI1 | L | L1/L2 | L3 | E | B1 | S | M | Z | TA [Nm] | M1 | |||

| 19 | 10 | 17 | 21 | 20 | 40 | 18 | 25 | 18 | 16 | 12 | 2 | M4 | 6 | 4,1 | M4 | 0,179 | 0,000044 | |

| 24 | 35 | 60 | 75 | 28 | 55 | 27 | 30 | 22 | 18 | 14 | 2 | M5 | 4 | 8,5 | M5 | 0,399 | 0,000191 | |

| 28 | 95 | 160 | 200 | 38 | 65 | 30 | 35 | 27 | 20 | 15 | 2,5 | M5 | 8 | 8,5 | M5 | 0,592 | 0,000418 | |

| 38 | 190 | 325 | 405 | 48 | 80 | 38 | 45 | 35 | 24 | 18 | 3 | M6 | 8 | 14 | M6 | 1,225 | 0,00129 | |

| 42 | 265 | 450 | 560 | 55 | 95 | 46 | 50 | 35 | 26 | 20 | 3 | M8 | 4 | 41 | M8 | 2,3 | 0,00317 | |

| 48 | 310 | 525 | 655 | 55 | 105 | 51 | 56 | 41 | 28 | 21 | 3,5 | M10 | 4 | 69 | M10 | 3,08 | 0,0052 | |

| 55 | 410 | 685 | 825 | 74 | 120 | 60 | 65 | 45 | 30 | 22 | 4 | M10 | 4 | 69 | M10 | 4,67 | 0,0103 | |

| 65 | 625 | 940 | 1175 | 70 | 135 | 68 | 75 | 55 | 35 | 26 | 4,5 | M12 | 4 | 120 | M12 | 6,7 | 0,0191 | |

| 75 | 1280 | 1920 | 2400 | 80 | 160 | 80 | 210 | 63 | 40 | 30 | 5 | M12 | 5 | 120 | M12 | 9,9 | 0,03968 | |

| 90 | 2400 | 3600 | 4500 | 105 | 200 | 100 | 100 | 75 | 45 | 34 | 5,5 | M16 | 5 | 295 | M16 | 17,7 | 0,1136 | |

| Size | Bore D and the respective transmittable friction torques TR in [Nm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ø 10 | Ø 11 | Ø 14 | Ø 15 | Ø 16 | Ø 19 | Ø 20 | Ø 24 | Ø 25 | Ø 28 | Ø 30 | Ø 32 | Ø 35 | Ø 38 | Ø 40 | Ø 42 | Ø 45 | Ø 48 | Ø 50 | Ø 55 | Ø 60 | Ø 65 | Ø 70 | Ø 80 | Ø 90 | Ø 95 | Ø 100 | Ø 105 | |

| 19 | 27 | 32 | 69 | 84 | 57 | 94 | 110 | |||||||||||||||||||||

| 24 | 70 | 87 | 56 | 97 | 114 | 116 | 133 | 192 | ||||||||||||||||||||

| 28 | 108 | 131 | 207 | 148 | 253 | 285 | 315 | 382 | 330 | 433 | 503 | |||||||||||||||||

| 38 | 208 | 353 | 395 | 439 | 531 | 463 | 603 | 593 | 689 | 793 | 776 | |||||||||||||||||

| 42 | 445 | 495 | 595 | 526 | 678 | 671 | 775 | 718 | 872 | 1043 | 1061 | |||||||||||||||||

| 48 | 616 | 704 | 899 | 896 | 1030 | 962 | 1160 | 1379 | 1222 | 1543 | ||||||||||||||||||

| 55 | 863 | 856 | 991 | 918 | 1119 | 1110 | 1247 | 1277 | 1665 | 1605 | 2008 | |||||||||||||||||

| 65 | 1446 | 1355 | 1637 | 1635 | 1827 | 1887 | 2429 | 2368 | 2930 | |||||||||||||||||||

| 75 | 1710 | 2053 | 2059 | 2294 | 2384 | 3040 | 2983 | 3664 | 4293 | |||||||||||||||||||

| 90 | 3845 | 4249 | 4794 | 5858 | 5900 | 7036 | 8047 | 9247 | 9575 | 10845 | ||||||||||||||||||