Peak performance metre by metre

Off highway machines

Joachim Grunwald

Head of Business Unit Coolers, KTR Germany

October 2023 • There can be few industrial sectors across the globe which come with such formidable requirements as mining. In order to drill tunnels into solid mountain rock to facilitate new transport routes or exploit underground mineral deposits, both human beings and technology need to deliver impressive peak performance. And frequently under difficult and dangerous conditions.

Transport logistics often become enormous challenges with large-scale projects, such as realising kilometre-long train or car tunnel tubes. Skilled workers and a broad spectrum of items need to be safely brought to and from respective locations, often over long distances and varying types of substrata. This is exactly where the Hermann Paus Maschinenfabrik company comes into play, fulfilling corresponding needs by developing and manufacturing suitable vehicles. "Each one is always individually tailored for a specific use, because every mining and tunnelling project is different," says project manager Lars Hauschild at Paus.

Safe personnel and material transport is essential

Founded in 1968 in Emsbüren, the Hermann Paus company mostly produces construction machinery, inclined elevators, aerial work platforms and cranes for international customers. Paus' well-engineered product portfolio for mining and tunnelling includes hydraulic liftgate trucks, load-haul-dump machines (LHDs), dump trucks and route maintenance vehicles. So as to meet the highly diverse construction project requirements flawlessly, vehicle solutions are individually designed based on standard platforms, which ensure reliable high quality during the production stage. After all, when below ground and far away from the next service facility, one has to untiringly rely on every machine’s intended functionality at each work-process stage.

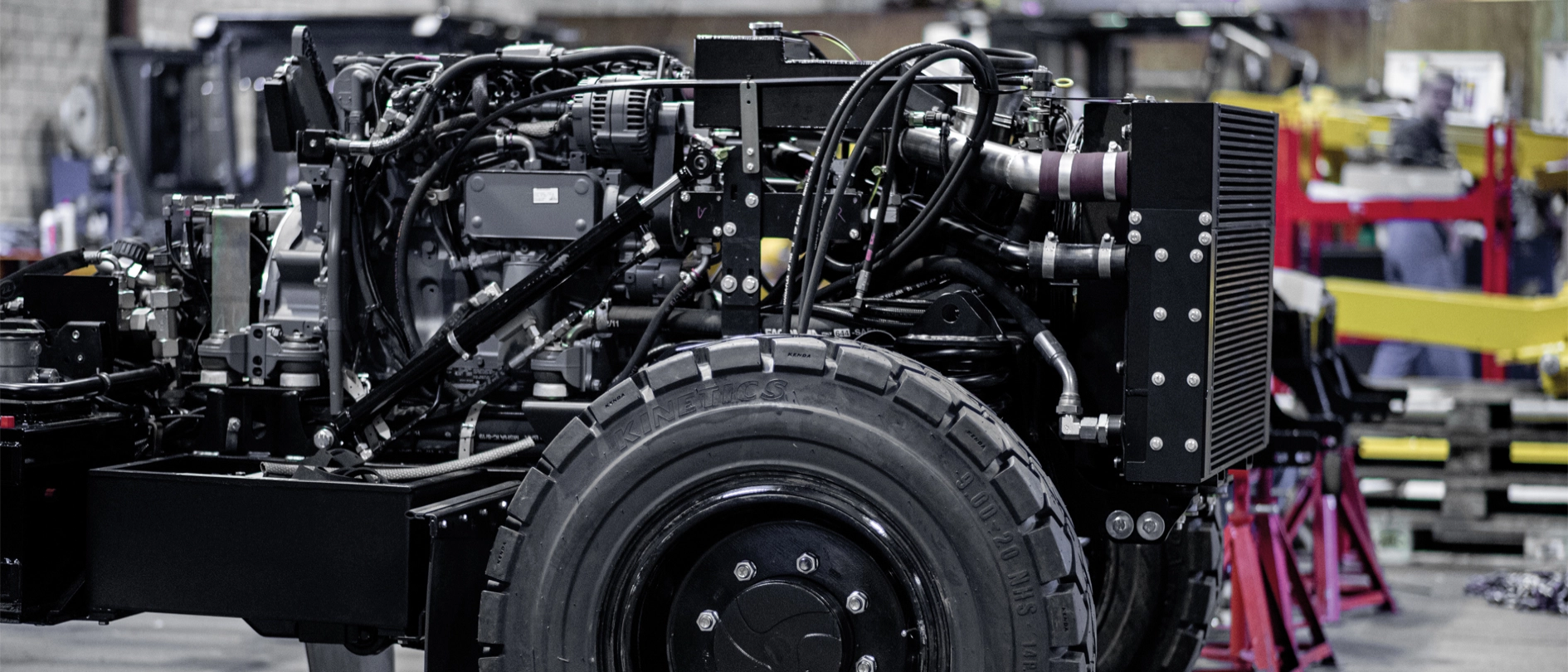

This is where MinCa series utility vehicles are exemplary. They are used for underground passenger and material transport as well as for special operations and can accommodate payloads of up to 4.0 tons. Various superstructures can be mounted onto a respective basic vehicle, converting it for example into an explosives transporter, service vehicles or fire engine. "In passenger transport, effective suspension significantly heightens ride comfort for all those on board. Ultimately trips usually take place over extremely rough and bumpy surfaces" Lars Hauschild explains. The compact robust construction of all basic models ensures their exceptional longevity even under harsh underground conditions. In addition to this, MinCa vehicles are very manoeuvrable – a feature, as in other areas, that is a great benefit in the narrow, often maze-like tunnel systems in mines.

We design and build our machines according to the individual requirements of our customers. Tailor-made and reliable this is how we create real added value. This is only possible with commitment and innovative partners.

Lars Hauschild

Project manager, Hermann Paus Maschinenfabrik

And as the metre-by-metre drift gradually turns into kilometres, the MinCa’s engines have to keep going with absolute reliability. Paus installs hydrostatic drives in its MinCa 5.1 and MinCa 18 while there is sufficient energy in the 5.1 E-series electric engine to work a whole shift. In combustion engine models, an MMC series cooling system sees to the cooling of charge air, cooling water and hydraulics. A torsionally rigid Bowex FLE-PA flange coupling provides the connection between the combustion engine and the hydraulic pump for the hydrostatic drive in the superstructures. With stationary applications in areas with little fresh air, the drive is switched to electric operation: in this case a ROTEX flexible jaw coupling with a bellhousing connects the electric motor and the hydraulic pump. With the help of such high-performance technology, MinCa transport vehicles are used daily to master mountains in the deepest of places anywhere on the planet.