Safety coupling available in various types

The safety coupling KTR-SI Compact is a backlash-free torque limiter available in various types (as a flange type and in combination with a backlash-free coupling ROTEX GS) and with various operating principles (ratchet type or synchronous type).

The backlash-free ball engagement system of the safety coupling is made of high-quality Q & T steel.

Highest precision and service life of our torque limiter are achieved by additional function surfaces and a special disk spring.

The solid safety coupling provides overload protection up to 3,100 Nm.

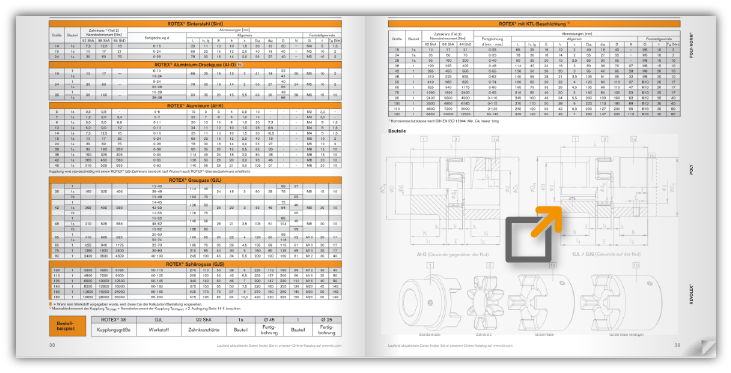

Our range of KTR-SI Compact safety coupling includes the backlash-free, load-separating safety coupling as a flange type (KTR-SI Compact FT) and load-separating safety coupling with a backlash-free coupling (KTR-SI Compact with ROTEX GS).

The safety coupling KTR-SI Compact FT is available with various operating principles (ratchet, synchronous, fail-safe, idle rotation).

Applications of our backlash-free safety coupling KTR-SI Compact:

conveying systems, packaging machines, textile machines, food-processing machines, special machine construction, servo drives, marine aplications

Overload coupling as a ratchet type DK:

Any engagement after an overload. After eliminating the overload, the balls re-engage automatically with the next following ball indentation.

Overload coupling as a synchronous type SR:

Synchronous engagement after an overload. After eliminating the overload, the balls re-engage automatically after a rotation of 360°. Driving and driven side are always placed in the same position to each other.- Other degrees of re-engagement, for example 180°, are also possible.

Information on selection of torque limiters:

To make sure the torque limiter is not released with process-related torque peaks already, the shifting torque of the coupling should exceed the maximum operating torque by at least 30 % (see diagramme).

Torque limiters and overload systems that re-engage automatically should be used with reduced speed with high release torques only.

Frequent or longer slipping or engaging increases wear of the torque limiter.

After the torque limiter has separated driving and driven side in case of overload, it may take some time before the drive stops due to large mass inertias in the drive train.

This may generate early wear of torque limiters and overload systems that re-engage automatically. That is why we recommend with drives with large mass inertias or higher speeds to use the overload system KTR-SI as an idle rotation version.

We basically recommend electrical monitoring of the torque limiter to disengage the drive immediately in case of overload. We will be pleased to assist you with any technical questions about the selection of torque limiters. For that purpose we dispose of latest simulation and calculation programs. The principle applies: the more detailed the data, the more precise are the calculation results.