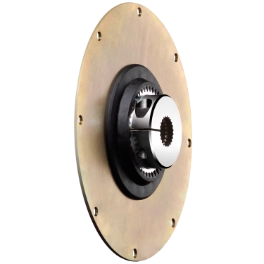

flange couplings

Flange couplings are available as torsionally stiff, torsionally flexible and highly flexible coupling versions. Depending on the combination of driving and driven machine the type is calculated by a torsional vibration analysis.

Mobile machines mainly use I. C.-engines for their drive. With hydrostatic drives hydraulic pumps are directly coupled, with mobile compressors the compressor unit is directly driven. Both units are connected by a flange coupling.

It has to comply with a number of specifications – primarily it has to transmit the power reliably so that the pending operations can be performed as requested.