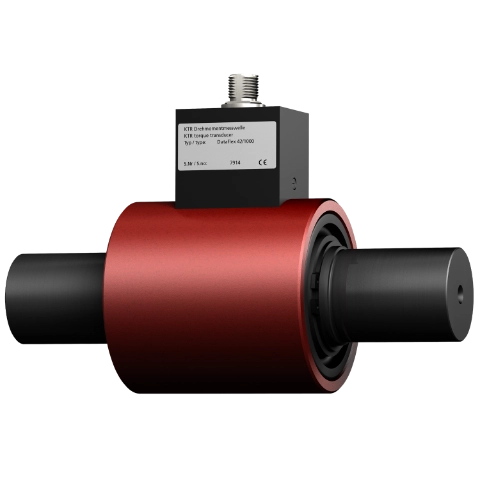

The DATAFLEX torque sensor is a torque measuring device available in eleven sizes to precisely measure torques from 10 Nm to 20 kNm.

Modern drive technology with its variable and dynamic drives cannot imagine to do without precise measuring of torque and speed. Our torque sensor DATAFLEX measures four parameters simultaneously: torque, speed, torsion angle and direction of rotation.

Measurement of torque is made via approved technology of wire strain gauges combined with state-of-the-art electronic components. The torque signals are processed contactlessly by our torque sensor with a high resolution of 24 bits reaching an accuracy of 0.1 % of the final value.

Features

Dual-range sensor 5:1

Inaccuracy 0.1 %

Integrated speed measurement

Direction signal

Output signal ±10 volts

Torque measuring shaft with two measuring ranges

A simple touch of a button switches the torque measuring shaft to a second measuring range amounting to one fifth of the nominal value. This allows significantly smaller torques to be precisely measured without having to change the test setup. In addition the measuring system has an encoder for calculating the speed. It provides two 90° phase-shifted signals and a scalable DC voltage for the speed.

Applications of DATAFLEX torque measuring shaft:

- machine monitoring

- process control

- test bench technology

High-power torque sensors

If requested, we manufacture customised torque sensors and torque measuring shafts for large measuring ranges from 20 kNm to 500 kNm. In this context key parameters such as measuring range, size, length and kind of connection can be adjusted to the specifications. The torque is measured contactlessly so that bearings are not required.

Apart from customised torque sensors KTR provides special solutions, for example with couplings equipped with torque measuring technology which require no or only few amendments of the customer setup.

Product Details

Specifications for: DATAFLEX® Torque measuring shaft

Further information and specifications can be found in our online catalogue.

Downloads

- Catalogue Drive technology PDF | 73 MB

- DATAFLEX 16/... Torque messuring shaft Operating/Assembly instructions 49014 PDF | 1 MB

- DATAFLEX 32/... Torque messuring shaft Operating/Assembly instructions 49015 PDF | 2 MB

- DATAFLEX 42/1000 Torque messuring shaft Operating/Assembly instructions 49016 PDF | 1 MB