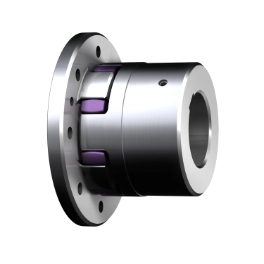

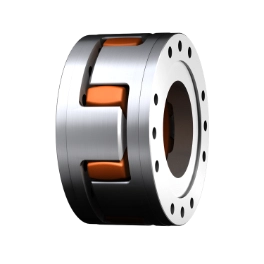

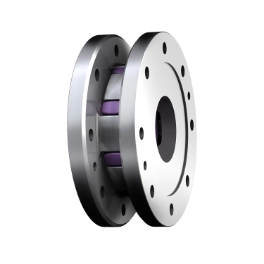

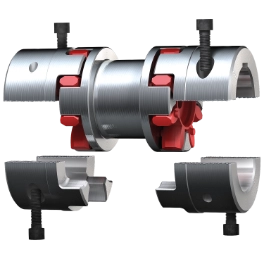

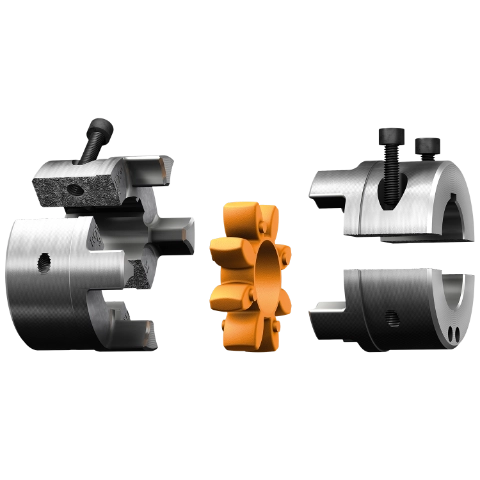

The torsionally flexible jaw coupling ROTEX SH is an elastomer coupling with split hubs / SPLIT hubs (half shell coupling) easy to service and is characterized by easy assembly and disassembly.

The hubs of the half shell coupling ROTEX SH have been split into two halves precisely, mechanically and reliably by "cracking". A rough surface with positive-locking connection ensuring an accurate fit of the two halves is generated. The contoured, rough cracked surfaces ensure ideal centering of the hub halves. The split hubs allow to assemble and disassemble the elastomer coupling radially via four screws without displacing the adjacent power packs. This makes the elastomer coupling with split clamping hub particularly easy to assemble and service.

Features

material cast iron

complying with ATEX (acc. to EU directive 2014/34/EU)

easy assembly/disassembly via four screws

centering of both hub halves through the cracked surface

displacing the power packs is not necessary for assembly

Product Details

Specifications for: ROTEX® SH

Further information and specifications can be found in our online catalogue.

CAD drawings

Find 2D CAD drawings for download here.

You need 3D drawings instead? Then please visit our 3D CAD library.