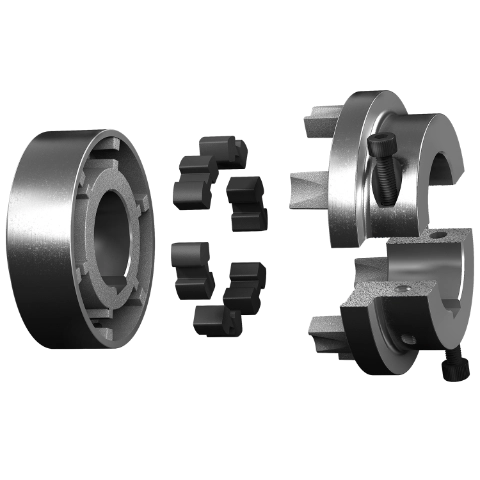

The torsionally flexible, failsafe shaft coupling ROFLEX SH Split is a short, three-part shaft coupling for torsional vibration damping power transmission.

The torsionally flexible jaw coupling ROFLEX SH Split is an elastomer coupling with fracture separated/cracked hubs (SH SPLIT). This design is also referred to as half shell coupling, clamping coupling, coupling with split hubs or elastomer coupling with split clamping hub.

The coupling transmits torques up to 1,800 Nm.

.

Features

three-part shaft coupling for torsional vibration-damping power transmission

axial plug-in, easy assembly

easy assembly/disassembly via four screws

compact: small shaft distance dimension

elastomer spider can be replaced when assembled

Product Details

Specifications for: ROFLEX® SH

Further information and specifications can be found in our online catalogue.

CAD drawings

Find 2D CAD drawings for download here.

You need 3D drawings instead? Then please visit our 3D CAD library.