J. Schneider Elektrotechnik | 50,777 megawatt - work for 133,000

Wind Power, Hydraulics

Eberhard Maier

Sales Engineer, KTR Germany

28,675 wind turbines were rotating on German soil at the end of 2017. According to statistical data from the German Wind Energy Association, this provided for an installed capacity of 50,777 megawatt. That in turn was approximately equivalent to more than 39 atomic pressurised water reactors – from a theoretical viewpoint. De facto Germany’s wind energy industry has developed into a major economic sector that, according to the Association, provided a livelihood for a total of 133,000 people in 2016.

Jobs span the wind turbine’s entire value chain – stretching far beyond construction and initial commissioning. It was with good reason that the municipal government of Gengenbach, a town in the state of Baden-Württemberg bordering the Central Black Forest, extensively involved its citizens in planning a four-turbined wind farm. Those who invested into it have been able to see their money working on the local hill ridges of Rauhkasten and Steinfirst.

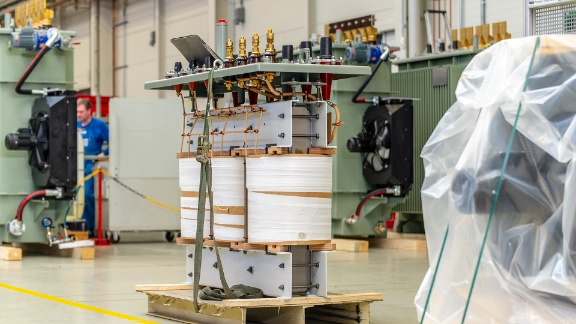

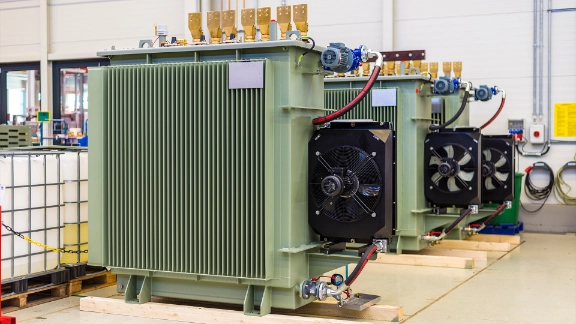

All four ENERCON E-115 wind energy converters each deliver a rated output of 3 megawatt and are designed for non-coastal locations with low-wind conditions. The turbines were erected on precast concrete towers with a hub height of 149 metres and have a rotor diameter of 115 metres. The generated electric power is fed into the local power grid using a tower-integrated transformer station. For this purpose, transformer specialists J. Schneider Elektrotechnik located in the city of Offenburg have integrated oil-insulated transformers with an output of 3,500 kilovolt-ampere in the tower bases. The transformer’s function is to convert the low voltage generated by the turbine into the usual medium voltage of 20 kilovolt.

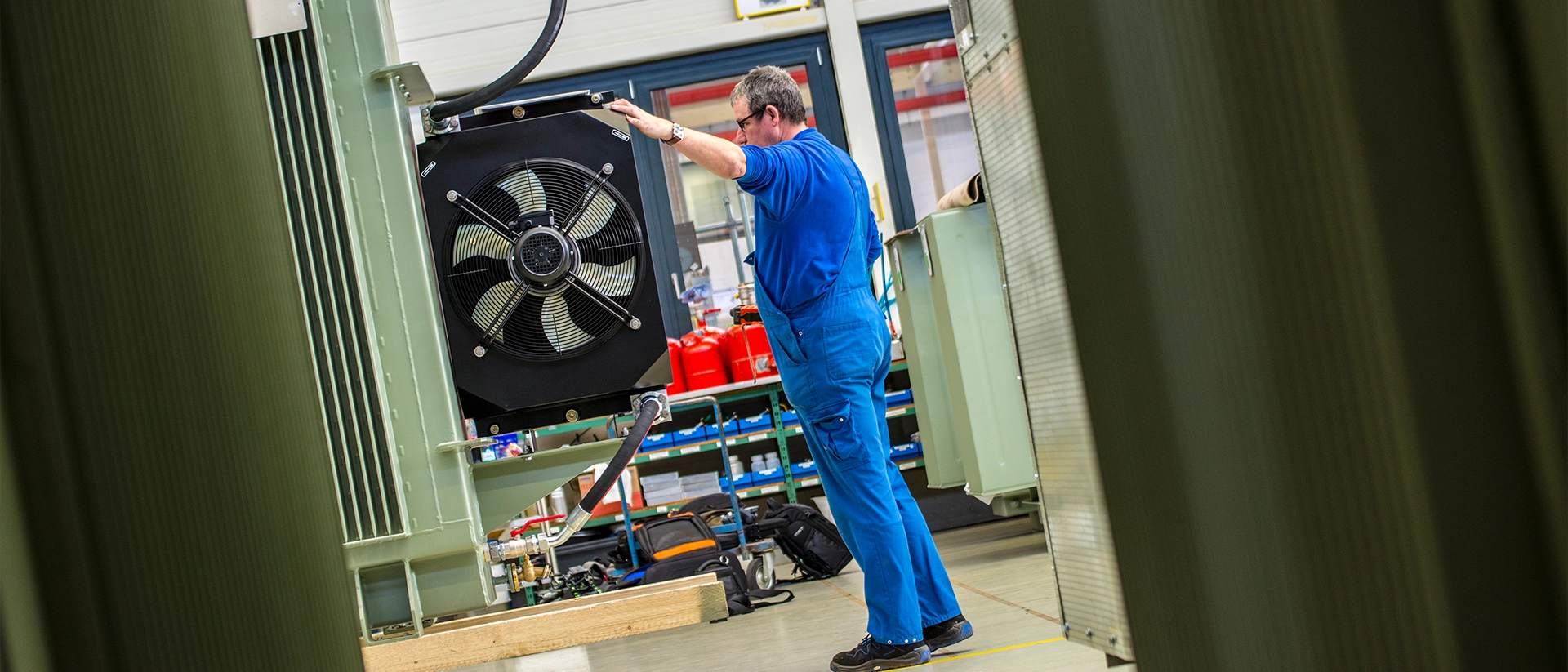

Every temperature change involves a change in pressure. The cooler must stand such fluctuations in pressure - which it does.

Thomas Hug

Technical Manager Transformers, J. Schneider Elektrotechnik

A characteristic challenge when installing transformers in wind turbines is making use of the very limited available space. This is especially the case when efficient cooling of insulating oil utilized to dissipate the loss of power in the form of heat is required. Because the service life of this crucial part was paramount to the Offenburg transformer specialists, they resorted to a KTR solution: the OAC oil and air cooler. Its compact design requires little installation space and above all, enables optimum use of the available ambient height. This paves the way for the integration of the entire feed-in technology into the tower, without having to build any additional buildings.