Hydraulic clamping and brake system with a failsafe function

07/14/2015

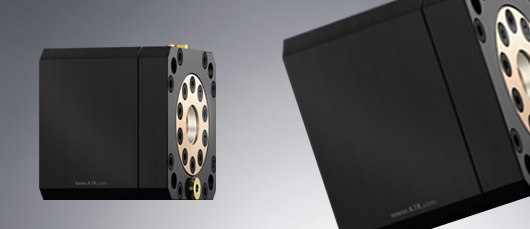

The passive clamping and brake system KTR-STOP® NC clamps the shafts from ball screw drives, linear drives or bar guides, holding tool tables and work pieces in place. The clamping increases the system stiffness and reduces vibrations ensuring an accurate manufacturing process. Additionally, the system offers a failsafe function: when unplanned loss of hydraulic pressure or an engine failure occurs the NC assumes the function of a brake and closes within milliseconds. The robust and compactly designed KTR-STOP® NC can be used as an integrated solution between engine and spindle or as a plug-in system at the end of the spindle. The new clamping and brake system is available in size 32 for shaft dimensions from 18 to 25 mm. The performance level includes a maximum holding torque of 110 Nm as well as a maximum holding force of 8,800 N. The dimensions of this series are 96 x 96 x 86 mm with a weight of 5.5 kg. Further sizes with a higher performance level are being planned.

Related Links