Off Highway Machines

Industries

Marie-Christin Maier

Industry manager Off Highway Machines and Agriculture

Every new generation of construction machines has to comply with increasingly stringent emission standards. In that regard the manufacturers make use of measures inside the engine or additional gas treatment. In every case there is high pressure for innovations in the industry as is the case with pressure on the designing departments, since every adaptation to new standards requires re-selection of the overall drive train.

Would you like to get a first insight? In our industry brochure you will find a complete overview of the entire range of components and areas of application for off highway machines.

Be it in sludge, rubble or gravel, sonstruction vehicles have to function reliably anytime, anyplace. This is where our trouble-free components come into their own!

Andreas Hücker

Product Manager of flange couplings - Off Highway Machines

Couplings, Cooler and brake systems for construction machines

Electric and hybrid drives in the higher performance range?

In addition, there is the claim for more and more compact designs resulting in a higher performance density and testing of alternative drive designs such as electric or hybrid machines. From the commercial point of view the manufacturers are reducing the number of suppliers who they purchase bigger and bigger performance packages from.

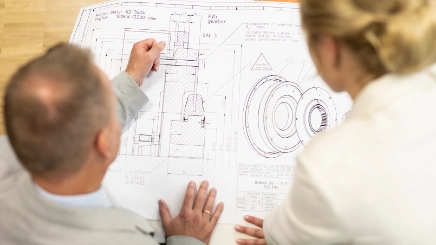

Being a development partner and supplier, we support our customers with adapting the drives to new specifications. Optimizing existing drives and coupling systems via torsional vibration calculations plays a big role here. The results can be verified in the KTR test field afterwards.

Fields of application

Our products are primarily used in:

- Compactors

- Diesel generators

- Dewatering pumps

- Hydraulic excavators

- Forklift trucks

- Mobile compressors

- Paver finishers

- Road cutters

- Telescopic handlers

- Wheel loaders

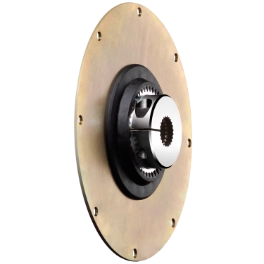

Couplings for construction machinery

Our couplings meet all demands on efficiency and power density even under demanding operating conditions. The portfolio includes torsionally stiff and highly flexible flange couplings, flexible jaw couplings and torsionally stiff gear couplings.

Coolers for construction machinery

Depending on the specifications of application, the tailor-made combined coolers type MMC combine various media such as oil, water, fuel and air in one single cooling system.

Brakes for construction machinery

Our hydraulic brake systems are based on the classic disk brake, available as an active or a passive design.