The reinvention of modularity

General drive technology

Rob Groothuis

Sales Engineer, KTR Benelux

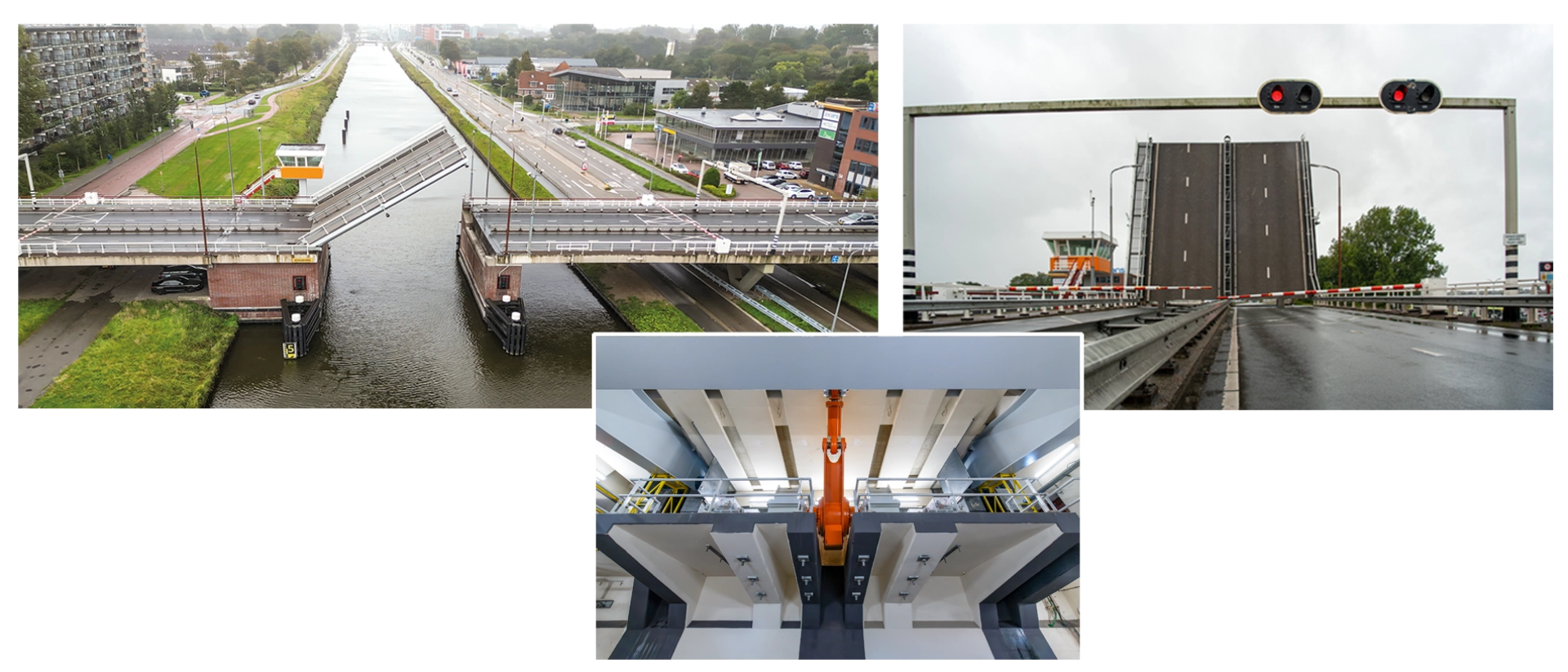

November 2025 • It's early morning on the North Holland Canal in Alkmaar as a section of asphalt on the 120 metre long Huiswaarder Bridge slowly rises, clearing the way for shipping. By contrast the road traffic flow is interrupted though only for a few minutes, partly because the intentional section separation is based on a precisely balanced interplay of energy, coordination and precision. Five decades after it was built in 1974, the bascule bridge’s original drive system was reaching the end of its useful service life. Downtimes were imminent and maintenance windows were becoming progressively shorter.

That is why the bridge has recently been retrofitted with the latest generation of technical components including electric motors, gear drives, manual controls and interfaces. This was planned by the bridge specialists at Technisch Adviesbureau Sliedrecht (TAS), realised by Machinefabriek Emmen (MFE) and linked with KTR couplings. This type of modernisation exemplifies how contemporary technology and engineering can be integrated with existing infrastructure without disrupting the flow of an entire city.

Reliability that safeguards traffic

The refurbishment began at TAS's drawing board. The Dutch consulting firm took on the design, invited tenders and supervised construction while coordinating all contractors during the whole process.

So as to attain the required torque, the entire drive system uses a mirrored configuration. On both sides, its hub consists of a SEW-Eurodrive 30 kilowatts electric motor. A ROTEX coupling with an integrated brake drum is mounted on the motor’s shaft. The torsionally flexible jaw coupling provides high-performance and reliable safety as the drum brakes retain the bridge leaf firmly regardless of its position.

A first helical bevel gear drive with a torque of 45,000 newton metres transmits power to a GEARex all-steel gear coupling that compensates for misalignment without compromising rigidity. A second and larger drive subsequently increases this torque to up to 592,000 newton metres. The downstream GEARex coupling then transmits this output to the crank arm, which lifts the hinged section. The new drive system ensures both unobstructed road and ship traffic at all times.

Integrating the all-steel gear coupling into the crank arm saves a lot of space. The mirrored principle allows the bearings of the gearbox on both sides of the crank arm to be used to support the movement mechanism.

Rob Groothuis

Sales Engineer, KTR Benelux

Consideration has also been given to potential emergency situations – for example in the event of a power failure the bridge can be operated manually using a handwheel. To enable this, a RADEX-NC servo coupling and a switchable ROTEX SD come into play, decoupling the electric motor and engaging the manual device.

Invisibly installed high-tech

So as to ensure that everything interacts smoothly, supervision is not carried out on site, but from a control room in Tesselsebrug. This is where Alkmaar's municipal utility company, Stadswerk 072, monitors every movement, measures wind speeds, registers braking cycles and assesses every load change – digitalisation that safeguards both the bridge mechanics and the flow of traffic.

The ultimate challenge lay in both dimensioning the components within a confined space as well as installing them with millimetre precision.

Marien van Bezooijen

Design engineer at TAS

"The ultimate challenge lay in both dimensioning the components within a confined space as well as installing them with millimetre precision", explains TAS design engineer Marien van Bezooijen. Before the new drive was installed, the structural framework had to be reinforced. In order to safely transfer the greater loads and torques into the structure, additional concrete supports were added to the existing concrete platform and installed in the bridge substructure underneath the road. These distribute the loads across the substructure and reliably transfer such forces into the foundations and subsoil.

And as the new drive system requires more power than the existing grid connection can provide, a Power and Energy Solutions system from SEW-Eurodrive has been used. Marien van Bezooijen: "The energy management system buffers load peaks, feeds back regenerative energy and thus increases efficiency and availability without having to expand the existing power infrastructure".

The Huiswaarder Bridge is now fully operational again and has the potential to become a flagship project for numerous other existing bridges in Europe whose drive systems date back to the 1970s. The collaborative endeavour between the municipality, TAS, MFE and KTR demonstrates that being a bridge builder necessitates timely teamwork.