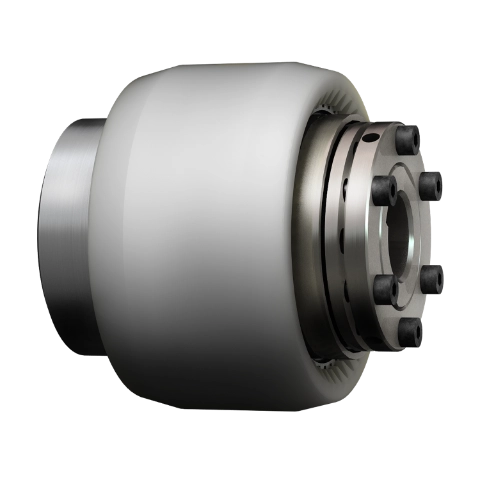

The torque limiter RUFLEX with BoWex gear coupling combines a torque limiter with a curved-tooth gear coupling for shaft-to-shaft connections.

BoWex curved-tooth gear couplings are flexible and torsionally stiff shaft connections for a positive-locking torque transmission and particularly suitable to offset axial, radial and angular shaft displacements.

Features

high displacements subject to double-cardanic design

low-cost torque protection for shaft-to-shaft connections

axially pluggable torque limiter

easy setting of slipping torque via standard tools

overload protection up to 400 Nm

Product Details

Specifications for: RUFLEX® with BoWex®

Further information and specifications can be found in our online catalogue.

CAD drawings

Find 2D CAD drawings for download here.

You need 3D drawings instead? Then please visit our 3D CAD library.