Neopost | Waste-free shipping

Automation

Rob Groothuis

Sales Engineer KTR Benelux

Is there such a thing as an ideal transport packaging size? There’s a precise answer to this: the packaging should fit like a glove so that the content can be inserted into it exactly! But this ideal situation applies to very few parcels and small packages. In online retailing, for example, large quantities of air and padding are transported and delivered because shippers restrict themselves to a limited number of packaging sizes.

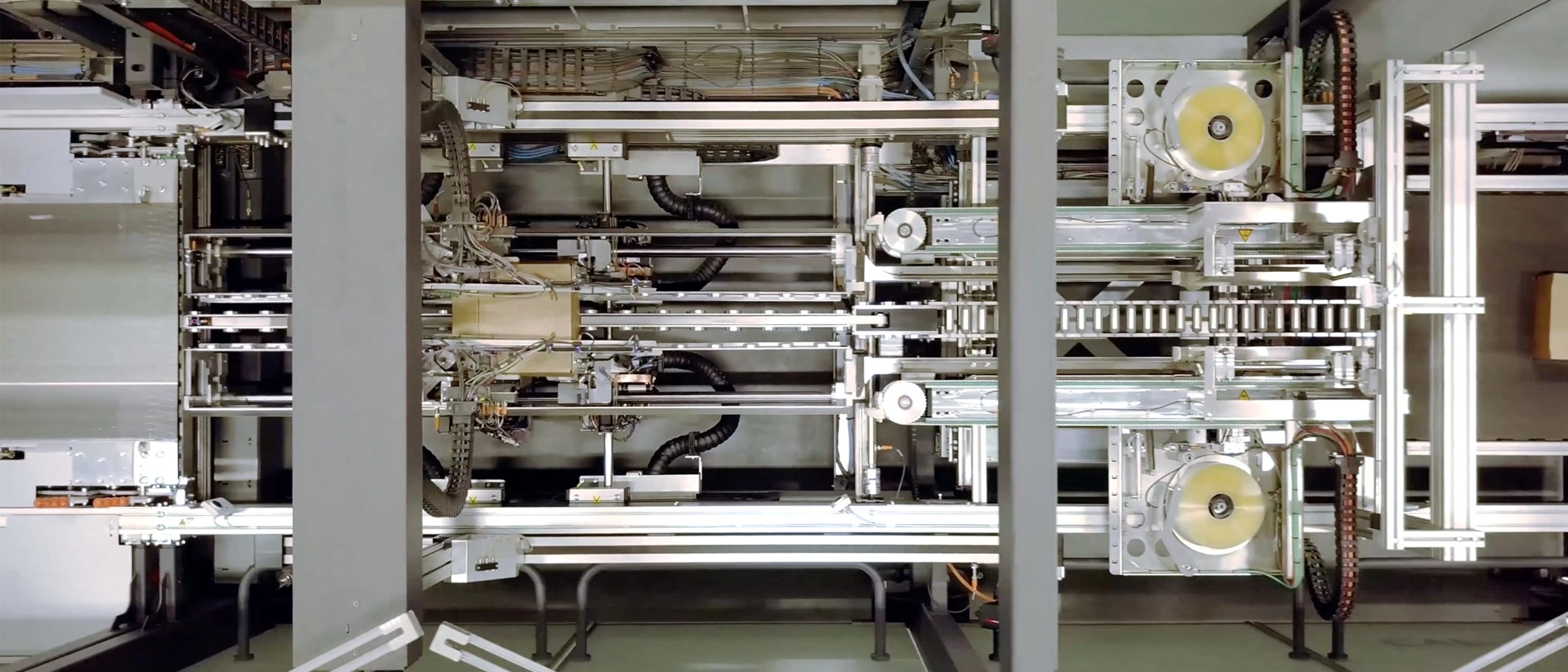

Companies using the CVP-500 packaging system made by Neopost are an exception to the status quo. In a first step, the company’s high-tech machine measures the goods to be packaged using a 3D scanner. In just a few steps, the CVP-500 then automatically folds and seals precisely fitting corrugated carton around the goods, applies a shipping label and the tailor-made packaging is ready to despatch. A further benefit of the CVP-500 is that it can pack several products into one carton, regardless of their size.

This technology delivers an optimally sized individual package every seven seconds. And the operator can make better use of truck space, has lower shipping costs and outgoings on packaging and padding – together with the feel-good factor that no resources are being wasted on transport packaging.

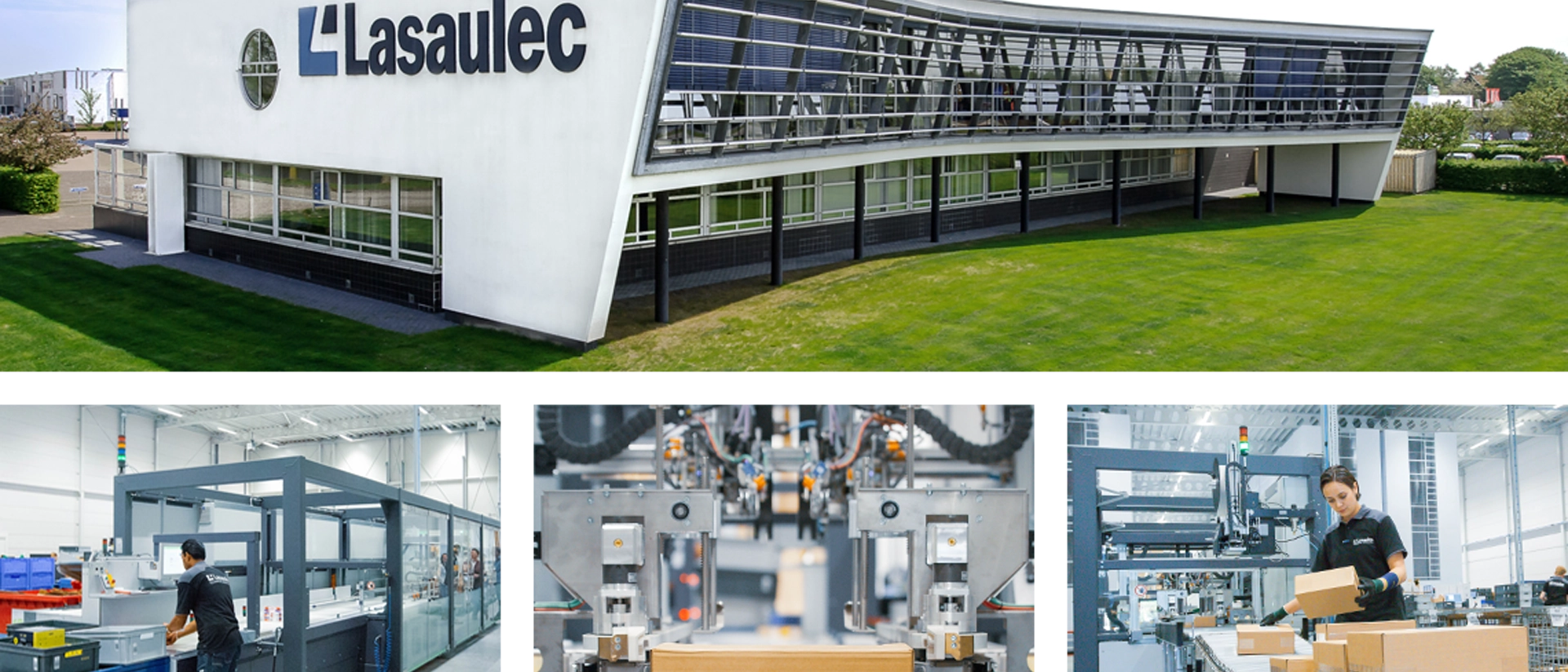

The machine was developed by Neopost Technologies B.V. in the Netherlands. Based in Drachten, the company is part of the Neopost Group and is globally active in processing mail, transport services and digital communication. With its highly awarded CVP-500, Neopost is now tapping into a new, rapidly growing market and primarily addresses numerous online traders worldwide.

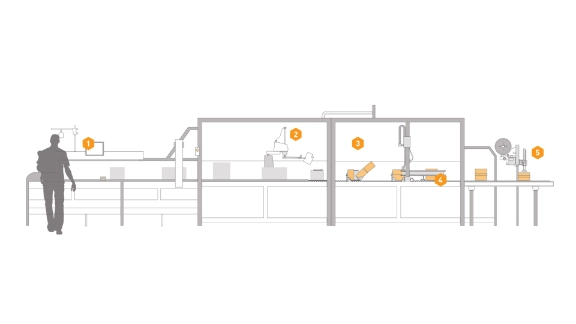

- Scanning the package

- Placing the invoice

- Folding the box

- Taping the box

- Placing the label

The CVP-500 is optimised to cater for a variety of dimensions, while both the size and quantity of the products to be boxed are completly flexible.

Hedde Biesma

Manager Marketing and Communications, Neopost Shipping

One of Neopost’s first-ever clients was Lasaulec B.V., a technical wholesaler located in Heerenveen, NL with its own online shop. According to the company's information, using this packaging system enables Lasaulec to save 150,000 to 200,000 euros annually on packaging materials. It also means the company can despatch many more parcels daily to its customers using a ‘same-day service’.

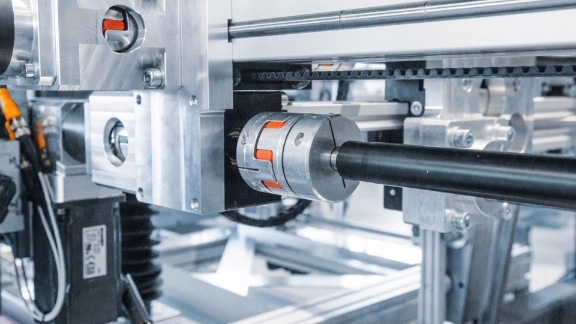

Different versions of KTR’s ROTEX GS series servo couplings are installed in the axes of the CVP-500. Diversely sized couplings made from differing materials with varying shore hardness enable the machine to convey, cut, fold and seal corrugated board. The couplings ensure reliable and precise positioning, contributing to the ideal transport packaging.

Precision and reliability were two key parameters. That's why Neopost chose to use our servo couplings in the CVP-500 linear drives.

Rob Groothuis

Sales Engineer, KTR Benelux