Triplex | Catching prey

Marine

Ørnulf Engkrog Gaarder

General Manager, KTR Norway

Modern trawlers no longer haul the catch aboard , they suck it instead. A fish pump hauls the animals from the net lying in the water straight into the bin, making maritime labour faster, easier and safer. Safety is what counts most on deck – specifically if rain, wind and swell request maximum performance from the crew. The same applies for winches and cranes the most essential feature of which is reliability whenever people are involved.

Today’s trawlers use modern crane systems

Everyone knows that fishermen speaking of a Triplex think of a winch unit comprising three cylinders, even if another manufacturer name is written on it. The Norwegians who are today members of the McGregor group of companies invented the winches and are proud of their generic brand name.

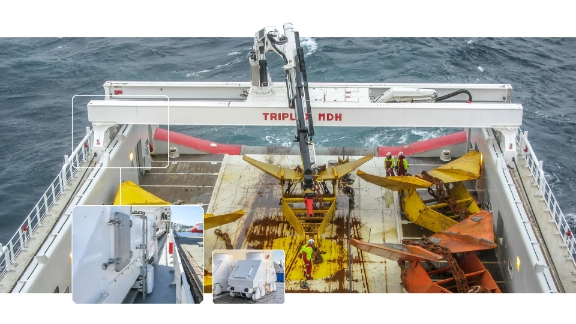

Apart from that Triplex stands for crane systems on deck of working vessels which are in turn connected with the multi deck handler. „Triplex MDH“ is comparable with a portal system positioning the crane mounted on top along the x and Y axis on deck. Its large lift and tow capacity makes the multi deck handler the crew’s perfect tool for handling large anchors, buoys and chains on deck.

„The crane weighs between 15 and 20 tons“, William Storvik, Marketing Manager at McGregor Triplex AS in Norwegian Averøy explains. To prevent the heavy equipment from moving with strong swell, hydraulic brakes hold firmly on the track. „The brakes fix the crane, thus have to be strong, sturdy and reliable“, Storvik says. The Scandinavian specialists for maritime handling and lifting technology favour hydraulic yaw brakes.

It's important that the brakes are strong, solid and reliable. The cranes weigh around 15-20 tonnes, and you don't want that runnig loose down the rails.

William Storvik

Marketing Manager, Triplex AS

Learning from applications in wind turbines

For Triplex KTR adapted type KTR-STOP YAW for special maritime applications, since actually the brakes‘ design originates from onshore wind turbines. „Seawater is always a challenge“, Ørnulf Engkrog Gaarder, CEO of KTR Norway says. The high demand on corrosion protection resulted in the use of chemically nickel-plated brake components. In a close cooperation with Triplex the housing was provided with a special coating structure with offshore classification C5 M.

There were other adaptations making the ready-made hydraulic yaw brake a maritime specialist. The striking feature is the spring system ensuring that the brake pads are immediately retracted when releasing to prevent useless wear.

On the high seas it is the long service life that counts, since maintenance and repair operations have to be performed outside any spacious shop. With that in mind another result of common engineering was to leave organic brake pads behind. In case of contamination with oily lubricants they lose their braking effect in the long term so that they have to be replaced. This work represents quite a different challenge on the high seas than onshore. That is why KTR provides the adapted yaw brake with special metallic-ceramic powder metal pads. They generate clamping torques up to 203 kN and 542 kN and are relatively insensitive to lubricants. With this technology Triplex confirm their title as leaders in technology at sea one more time.