"We let incredible forces work with precision"

Trainers are true multi-talents. They not only find and promote the right applicants, but also impart knowledge and take on important socio-pedagogical tasks and activities. We asked our trainers for cutting machine operators, Christian Fröse and Raphael Tepe, about their everyday work life and challenges.

"What exactly does one actually do as a cutting machine operator?”

Christian Fröse: "Cutting machine operators manufacture components, e.g. for machines or engines. For this, they work with CNC lathes, turning lathes, milling and grinding machines. Nowadays it is often said that you only have to push buttons on the machines. But that is not true. Among many other things, it is important to know how to plan something yourself, when which material is best used for a component and how to proceed most efficiently. In addition, our trainees have to learn to work with conventional machines and each of them must also have held a file in their hands at some point. After all, it is not self-evident that metal can be cut like butter".

Raphael Tepe: "Exactly! Key qualifications, specialist knowledge and individual problem-solving skills are still decisive for the profession today - and will remain so in the future.”

"What is particularly important to you as trainers?"

Christian Fröse: "It is important to us that potential trainees have a real desire to tinker and learn something new even before they start their apprenticeship. If you have already tinkered and tried out at home, for example on your own moped, because a part broke off or did not work properly, then that is a great prerequisite. The cool thing is, that at some point in your training you realize that you can make everything yourself, even if the part has never existed before. There are hardly any limits to creativity in our profession!"

Raphael Tepe: "It's also important for us to pass on our fascination for machining. Because we are both passionate about this profession and of course we want to pass on this joy. It is not blunt metalworking, as many people imagine. You have to imagine it more like unbelievable forces, which we make work with high precision".

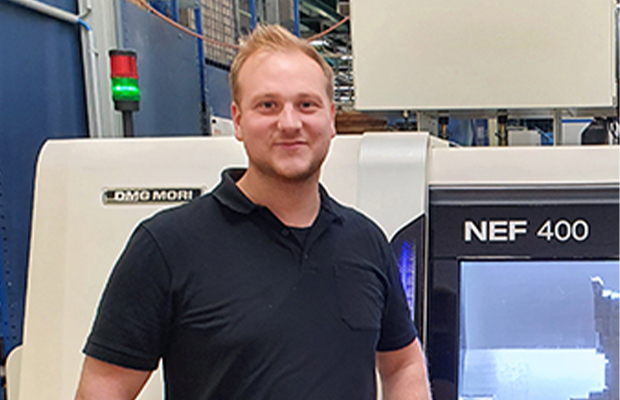

Christian Fröse

started working with us at the age of 17. At that time, his first steps here were as an apprentice for cutting machine tools in the turning department. Today he is a master craftsman and trainer with us.

Raphael Tepe

has been with KTR for 7 years and also trained with us as a cutting machine operator in the field of milling technology. He will complete his industrial foreman in the metal sector in October.

Christian Fröse: "Another important point is that we have decided to train project-oriented. This means that we let trainees work on individual projects, i.e. on complex assemblies such as air motors. This means that 40-50 parts have to fit together and function. The great thing is that if something really doesn't work, you have to think about why. In this way, we promote problem- and solution-oriented thinking. We let the trainees work independently, as far as possible, in a team so that they can develop strategies and possible approaches together. It is important to us that the trainees have at least one major interrelated project per year. The trainees from the first year of training are even starting to do so. Once they have learned the first techniques and machines, they can start working on a locomotive project. This is always something very special, because it is always finished just in time for Christmas and is therefore a great gift".

"At the moment we do not have any girls as apprentices in the field of machining, what is the reason for that?"

Christian Fröse: "We would like to train girls one day, but not because of the quota! It is important to us that all of our apprentices are hired according to the same criteria. For us it is relevant that the character fits the group and that you have a lot of fun doing handicrafts and tinkering. Everything else you need, you learn later. Good training is very important to us, because we want to take on all trainees after their apprenticeship".

"What do you think supports the trainees the most?"

Raphael Tepe: "We have a large learning workshop for all apprentices, so all apprentices work with each other over the course of the year and can exchange ideas and learn from each other. From my own experience I can say that even in the 3rd year of apprenticeship it is still helpful to look over the shoulder of the new apprentices of the 1st year. Then you don't forget the basics and internalize them once again."

Christian Fröse: "In addition to this, independent work is also an important criterion for the trainees. This promotes their own creativity in order to find solutions themselves".

"What do you enjoy most as trainers?"

Raphael Tepe: "It is especially nice to see the fascination on the faces of trainees who were previously unable to grasp the complexity of the profession, when they have completed their training and can now see what they have learned and can realize."

Christian Fröse: "I absolutely agree with Raphael! Just as great is the rapid development within the 3 years that we can observe with the trainees".

Many thanks for the interview, Christian and Raphael!