Börger | Wastewater treatment plant in Swiss Alps

Pumps and Compressors

René Pottmann

Sales Engineer, KTR Germany

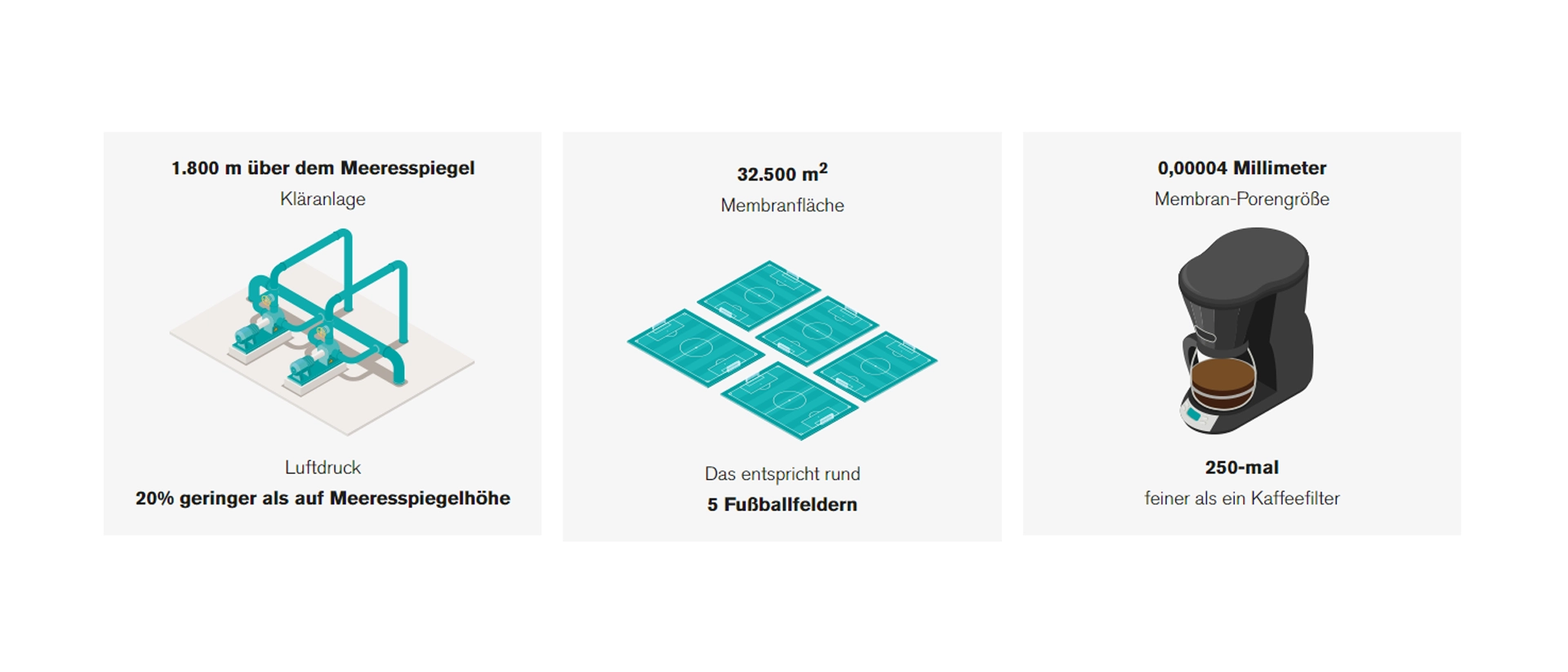

Where does one ideally build a sewage treatment plant in a narrow valley so that a municipality’s wastewater is best treated in a way not to trouble tourists during the holiday season? Inside an Alpine massif? Back in 1977 the town of Zermatt decided to do exactly this. Five years were needed until the plant started operating in 1982, followed by a progressive modernisation programme. Today Switzerland’s largest membrane bioreactor with a filter area of 32,500 square metres – about the size of five football pitches – functions behind closed doors. Following biodegradation processes, the hollow section fibre pores retain any particles larger than 0.00004 millimetres. "No bacteria can squeeze through them", says Beni Zenhäusern, Head of the Wastewater Treatment Plant in Zermatt. The necessary vacuum is provided by a Börger permeate pump that effectively sucks the biologically purified water through the filter cartridges.

Down in winter, up again in summer

After leaving the slopes for après-ski, winter sports enthusiasts leap under a hot shower before taking dinner at an inn or hotel restaurant. "We live off tourism", continues Swiss local Zenhäusern who vividly compares a double holiday season to two camel humps. After the snow enthusiasts dash down the slopes in winter, hikers scramble back up again in summer. Having two peak seasons a year means the Zermatt wastewater treatment plants accordingly have to deliver top performance and are correspondingly designed to cater for 76,000 people. What is astonishing is that the locals at the foot of the Matterhorn number less than 6,000 and this vast high difference results in part from overnight stays. But the real disparity stems from gastronomic businesses providing at least three sets of meals per day that drive up the chemical oxygen demand in wastewater treatment.

High output density in a confined space

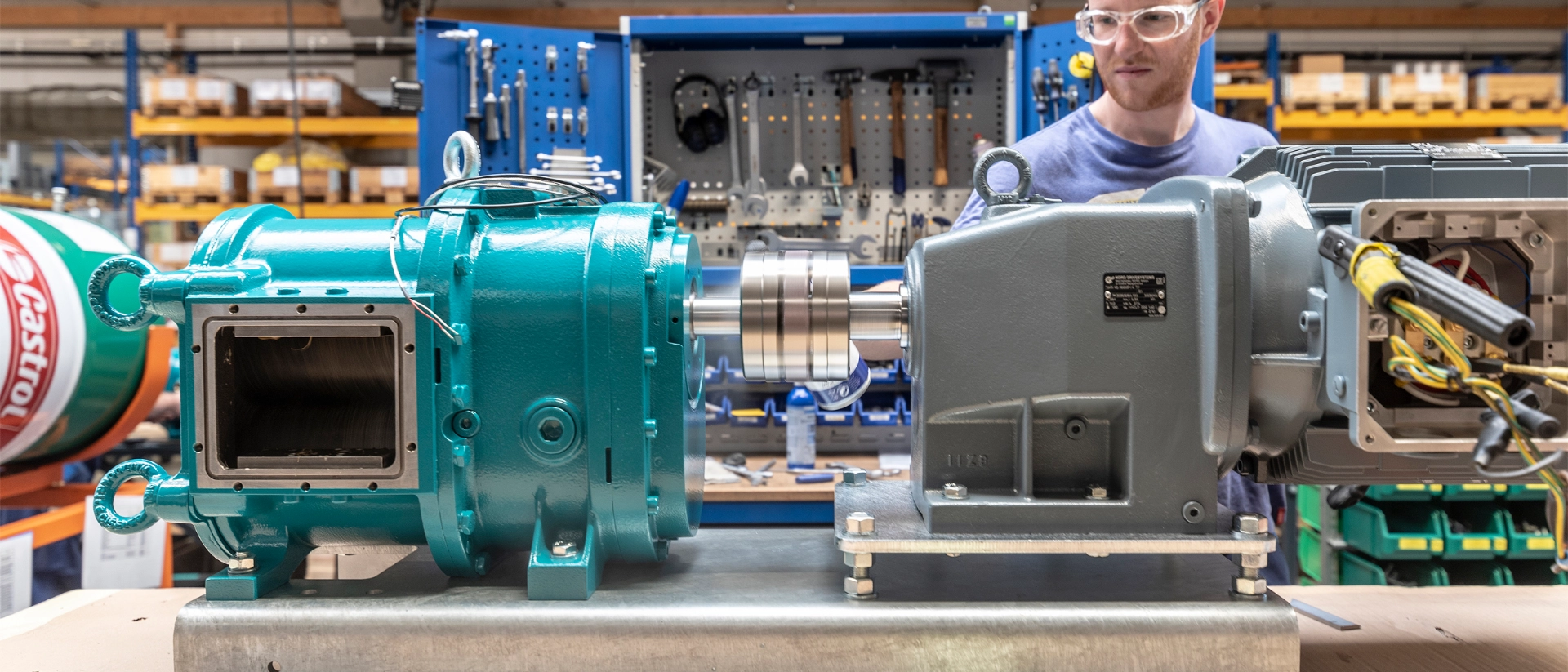

Given the limited space in the Swiss Alpine rock hollows, the energy requirements can only be fulfilled using process technology which works extremely efficiently. This is why membrane filters are used for the final treatment stage in the Zermatt plant. The Börger rotary lobe pumps provide the necessary vacuum during filter operations. A flexible ROTEX jaw coupling is used between the pump and the drive motor to intercept torque shocks during start-up and as a result of pressure fluctuations. This also applies in reverse operation, when the pump switches and flushes the membrane filters.

Zermatt was a challange for us because the plant is 1,800 meters above sea level. There are other air pressure conditions here which we needed to take into account when designing the pump.

Stefan Hülsmann

Sales Manager Börger for Germany, Austria and Switzerland

The design of the Classic EL 1550 pump was no trivial affair, especially as the sewage treatment plant is 1,800 metres above sea level. Such altitudes have noticeable impacts on air pressure: in simple terms, every eight metres upwards results in a decrease of one hectopascal. This means air pressure in Zermatt is about 20 percent less than at sea level causing a shortness of breath for both people and pumps due to the thin air. The consequence for the permeate pumps is a tendency to increased cavitation due to the lack of pressure on the wastewater’s surface. Cavitation here refers to the formation in a liquid flow of water vapour bubbles which tend to explode. This is also cause for concern especially in shipping and results in reduced efficiency as well as potential damage to rotors. "With this in mind, we designed a larger pump for the Swiss Alps, aimed at reducing rotational speed and thus effectively counteracting cavitation", explains Stefan Hülsmann, Börger Sales Manager for Germany, Austria and Switzerland.

A further interesting detail relating to Zermatt’s sewage is its temperature: it is warmer in winter than in summer! This phenomenon, according to Beni Zenhäusern, has two causes. In winter people take longer and hotter showers. And on account of sub-zero temperatures outside, surface water does not flow through the canals.