Targeting company standards and special ambient conditions

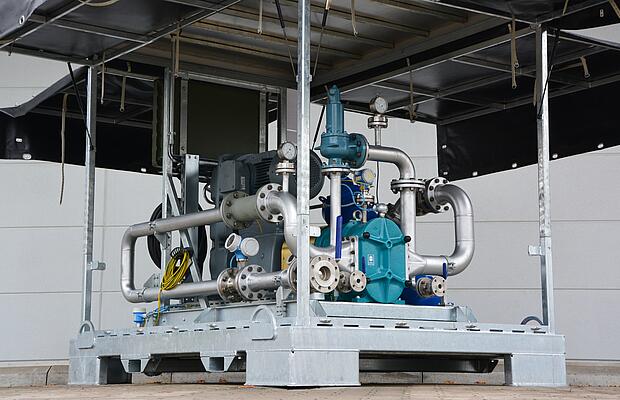

Pumps and compressors make up about one third of energy consumption in industry. Consequently the market is big with the portfolio ranging from miniature laboratory pumps to large-scale plants for petrochemistry.

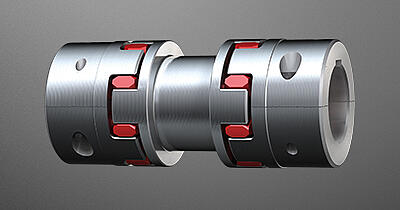

An essential function of the coupling is the ability to compensate for displacements in the drive train. That is why double-cardanic couplings are often used. Apart from that radial assembly and disassembly without dismounting adjacent drive components is a vital demand from the part of process and petrochemistry.

Torsional flexibility and damping of vibrations is required to increase the service life of the overall pump drive. Another specification is conformity with industry standards (API, ATEX etc.) and company standards.

We offer an extraordinarily wide range of couplings up to a maximum of 280,000 Nm to the manufacturers and users of pumps and compressors. Some series were specifically developed for this industry. Here the focus is on the users’ request to increase the pump’s service life, availability and efficiency by selecting the optimum coupling.

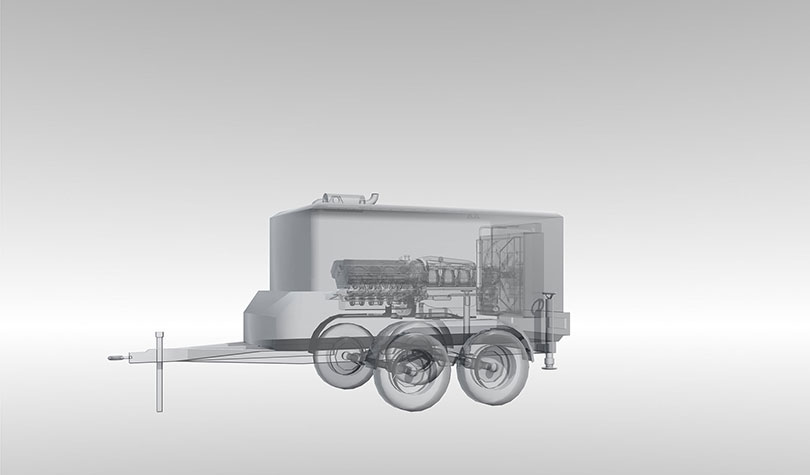

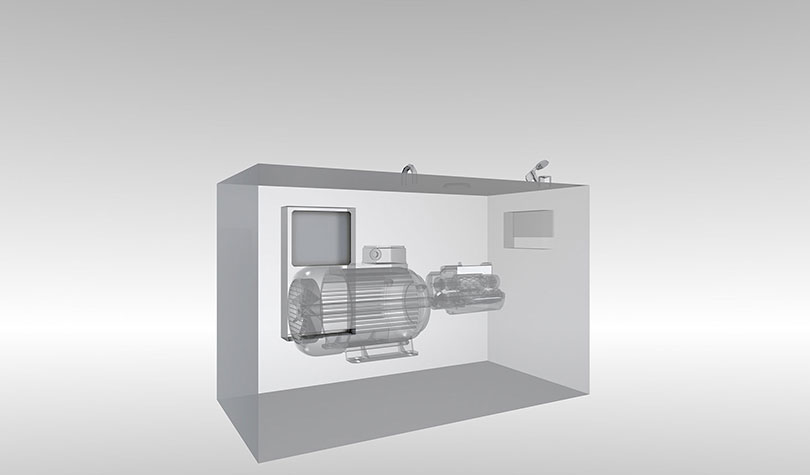

Being a listed and approved supplier of large companies in chemical and oil industry like Saudi Aramco and PDO, we are working closely with the customers developing special solutions that are tested in our test field at our headquarters in Rheine. The couplings comply with the API standards. The product portfolio includes both series for potentially explosive atmospheres and couplings with integrated overload protection or electronic torque monitoring as well as magnetic couplings for contactless torque transmission.

Contact

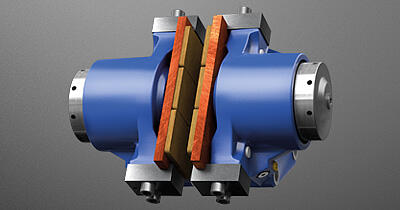

EVOLASTIC® E/EP

Individual elastomer version for a wide range of applications.

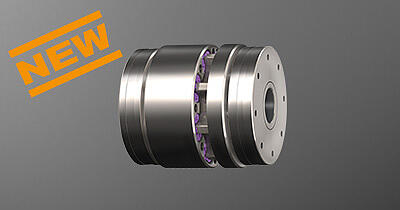

RADEX®-N NANA1(NANA2)

Three-part coupling type with spacer radially mountable

Find the right product quickly and easily with the KTR product finder

Product finder

MINEX®-S with containment shroud made of stainless steel

For lower performance ranges

DATAFLEX

Rotating shaft for measuring the most important drive data simultaneously: torque, speed, rotation angle and direction

Bellhousing made of aluminium

Circular and rectangular type on the pump side

Filler necks and oil level sight glasses

Visual monitoring of level / filling of oil tank

IntelliRamp®

Control system for program-controlled, accurate braking processes

KTR-SI FRE flange type

Idle rotation overload coupling with flange type

KTR-STOP RL S

Rotor lock for wind turbines of the smaller performance class

KTR-STOP® active fixed caliper brake

Service brake optionally with adjustment of air gap

MONOLASTIC® type with 3 holes

One-piece flange coupling with bore pattern with 3 holes

OAC

High-performance cooling for stationary and mobile hydraulics

Precision joint with plain bearing G/GD

Cardan shaft with plain bearing

RIGIFLEX®-N

Steel laminae coupling in accordance with API 610 and optionally API 671

ROTEX® GS HP

Very high speeds, for example main spindle drives and test benches

OTV - oil temperature control valve

For monitoring/controlling the temperatures of different liquids in vehicles, machines and gearboxes.

Pump mounting flange

For mounting hydraulic pumps to the diesel engine

Temperature probe TE-PT 100

Resistor temperature probe for temperature ranges up to 100 °C

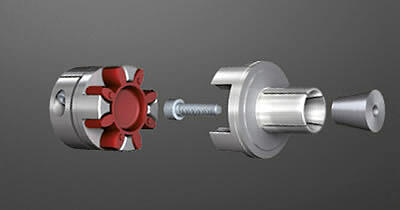

TOOLFLEX® Mini

Miniature bellow-type coupling - backlash-free and easy to assemble

CLAMPEX® KTR 400

Self-centering clamping element with utmost performance data

ROTEX® GS ZR2

Cardan shaft, intermediate pipe made of steel variable in length

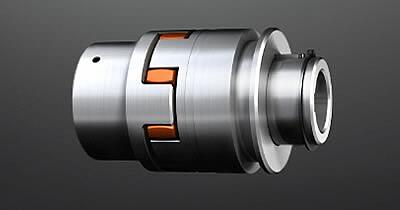

ROTEX® ZS-DKM-H

drop-out center design coupling, radial assembly/disassembly

CLAMPEX® KTR 225

Combines internal diameter of hub with various shaft diameters

ROTEX® GS ZR3

Cardan shaft, intermediate pipe made of aluminium variable in length

ROTEX® ZS-DKM-SH

Double-cardanic drop-out center design coupling, radial assembly/disassembly

MMC hydraulic cooler

For hydraulic oil, gear oil, lubricating oil, engine oil and water glycol

Oil/water cooler PHE

Plate heat exchanger with soldered plates made of stainless steel

RADEX®-N NANA 3 (API 610)

Three-part coupling type acc. to API 610 with radially mountable spacer

Bellhousing (cast iron) PG

Circular and rectangular type on the motor side

BoWex-ELASTIC® HE3(HE4)HE-D

Short highly flexible flange coupling made of steel

BoWex® junior M

Gear coupling made of nylon, three-part, plug-in, maintenance-free

EMB-STOP S-P-xx-F

electric, passive disk brake - medium force range

GEARex® FB

Both hubs are turned outside. One-piece sleeve acc. to AGMA standard

KTR-SI Compact with backlash-free ROTEX® GS

Load-separating safety coupling with backlash-free ROTEX® GS

KTR-SI FRA with POLY-NORM®

Overload coupling with torsionally flexible POLY-NORM®

KTR-SI FRE with ROTEX®

Idle rotation overload coupling in combination with ROTEX

KTR-STOP RL M

Rotor lock for wind turbines of the medium performance class

MINEX®-S with containment shroud made of Hastelloy

For average to high performance ranges

Oil/water cooler TAK/TP

Bundle of pipes heat exchanger: bundles of pipes are replaceable

OPC

Bypass flow cooling with integrated pump

Precision joint with needle bearing H/HD

Precision joints with needle bearing

RIGIFLEX®-N A-H

Steel laminae coupling in a half shell design according to API 610 and optionally API 671

ROTEX® for taper clamping sleeve

Can be combined with taper clamping sleeves

Bellhousing (made of steel) PS

Bellhousing made of steel for special demands

Mounting flanges ZO and gaskets

Facilitates disassembly of a motor-pump-unit

Elastic flanges

Structure-borne noise separation of pressure and suction lines

Rigid shaft couplings CLAMPEX KTR 700

Rigid shaft couplings for backlash-free, bending and torsionally stiff shaft-to-shaft connection. Among others, CLAMPEX®

KTR clamping nuts

Clamping Nuts for secure all-round claping force. With our clamping nuts large screw connections can be easily pretensio

ROTEX® DFN

Flange connection on both sides, screwing of driving and driven side

EMB-STOP M-P-xxx-F

electric, passive safety brake - high braking forces

EMB-STOP SBT

For ship propulsions up to 25 MW per propeller shaft

ETP-CLASSIC (Type R inclus)

Bague compétitive pour application standard et INOX

ETP-Express (Type R inclus)

Montage rapide par une seule vis et design compact

ETP-HYLOC

Charges lourdes et montage rapide par pompe séparée

ETP-MINI (Type R inclus)

Serrage rapide pour petit composant et INOX

ETP-OCTOPUS

Repositionnements précis et fréquents par pompe séparée

ETP-POWER

Montage rapide, fortes charges radiales

ETP-TECHNO

Montage rapide, haute précision et montages fréquents

Fluid coupling / Hydrodynamic coupling

smooth start-up of the machine - e. g. for conveyor belts

GEARex® DH

Type for large shaft distance dimensions with sleeve as cover design

Industrial controller

For monitoring and controlling the temperatures of liquids

MINEX®-S subassemblies and conversion kits

For customized special solutions and adaptations

MONITEX BT

MONITEX BT - Torque measuring coupling hub

REVOLEX® KX-D SB

Flexible pin & bush coupling with brake disk REVOLEX® KX-D SB | KTR

REVOLEX® KX-D with clamping set KTR 650

Type with clamping set, frictionally engaged torque transmission

Electronic level temperature switch NVT-E

Electrical monitoring of level and temperature

GEARex® FAB

Mounting position of hubs is different. One-piece sleeve acc. to AGMA standard

MINEX®-S with containment shroud made of PEEK

For maximum efficiency without any losses of eddy current

PIK

Bellhousing with integrated oil/air cooler PIK

Precision joint extendable GA/HA

Extendable precision joints with plain bearing or needle bearing

Steel tank BNK

Manufacture of tanks (steel tanks) acc. to DIN 24339:2016-04

SYNTEX®-NC with TOOLFLEX

Safety clutch with torsionally rigid metal bellows clutch

Tank heater TEHM

Tank heater with magnetic clamp for heating of oils

BoWex-ELASTIC® HE-ZS(HEW-ZS)

Highly flexible, radially dismountable flange coupling

BoWex® M-C

Gear coupling with sleeve made of polyamide, three-part, plug-in, maintenance-free

EMB-STOP XS-A-xx-F

Brake for low performance ranges

EVOLASTIC® EFH/EFHP

Highly flexible flange coupling for various applications

GEARex® DA

Sleeve with cover design for easy assembly resp. inspection of spline

KTR-STOP L light-xxx

Very compact holding or safety brake for high torque side

MINEX®-S with containmant shroud made of ceramics

For maximum efficiency without any losses of eddy current

POLY-NORM® ADR-SB

Shaft coupling with brake disk, radial disassembly possible

Precision joint made of stainless steel X/XD

Precision joint made of stainless steel with plain bearing

RADEX®-N NN

Two-part type without spacer compensating for axial and angular displacements.

SYNTEX® with backlash-free ROTEX® GS

Safety coupling with backlash-free servo coupling

Temperature switch TSC

Switching temperatures: 40 °C, 50 °C 60 °C, 70 °C and 80 °C

Damping ring D

Noise reduction with high strength at the same time

EMB-STOP S-A-xx-F

Electrical active holding brake for low and medium performance ranges

BoWex® stainless steel

Gear coupling with hubs made of stainless steel, three-part, plug-in, maintenance-free

MINEX®-S entirely made of stainless steel

Magnetic coupling entirely made of stainless steel

Precision joint with quick lock GR/HR

Quick-lock coupling with plain bearing or needle bearing

Damping rings DT/DTV

For structure-borne noise separation of the motor-pump-unit

EMB-STOP L-A-xxx-F

For high performance ranges, compact compared to Lever

EVOLASTIC® DFH

Highly flexible flange coupling with intermediate shaft in customised shaft distances

GEARex® DAB

Each one hub is turned outside resp. inside. Sleeve with cover design.

POLY-NORM® AZR standard drop-out center design coupling

With standard drop-out center design parts for large shaft distances

GEARex® FH

Type for large shaft distance dimensions. Standard AGMA sleeve

RADEX®-N NENE

Double-cardanic standard series with short shaft distance dimension