Project CAS

10/10/2018

Generation of heat or settling effects in the machine may cause unexpectedly big shaft displacements between motor and pump respectively compressor. One result may be that the shaft coupling no longer compensates for big displacements, is damaged and fails. The consequence is a sudden standstill of the machine which will cost the user dear. As a preventive measure the alignment of the drive train needs to be regularly inspected. For that purpose the machine has to be stopped which results in standstill costs. It is true that such procedure reduces the risk of failure, but does not avoid it, since often displacements are generated only when the machine is operating. The shaft displacements are no longer measurable at standstill.

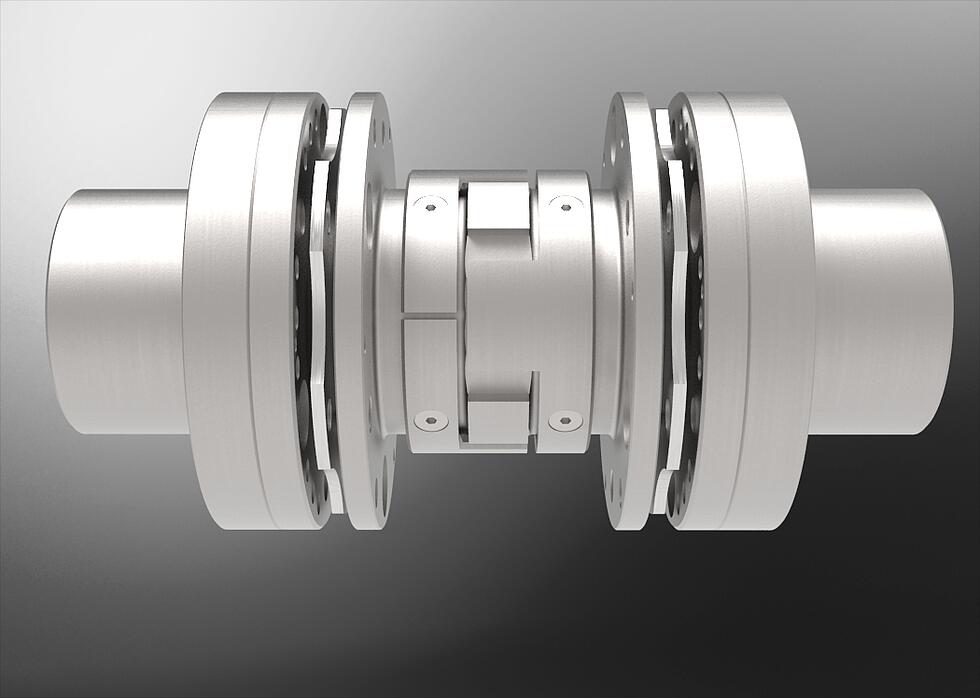

With the „Coupling Alignment Scan“, in brief: CAS, we will present you a system permanently monitoring the radial and angular displacements of the coupling while signalling serious shaft displacements immediately. In addition CAS provides for the option of recording the process of displacements in order to retrace loads with various operating conditions. The system consists of a double-cardanic steel lamina coupling in combination with a sensor. In this case the sensor measures the direction and extent of shaft displacements calculating the displacement figures of the coupling.

Main applications are as follows:

- chemistry/petrochemistry

- oil/gas

- hot water and heat media

- energy technology

- wastewater technology