Cooling systems from KTR – image video now online

17/09/2025 / Products

KTR Systems GmbH

Rheine

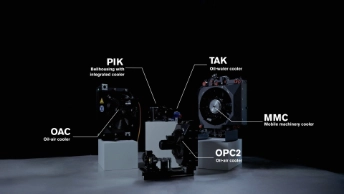

Our cooling systems are available either as custom-made or standard solutions; as multi-medium coolers, oil-air coolers or oil-water coolers; for use in mobile machinery or stationary hydraulics; optionally in maritime or ATEX versions.

Cooling performance test bench at KTR’s headquarters

The test bench is a combination of a wind tunnel and various units that convey and regulate the temperature of the media to be cooled. The cooling systems tested here are primarily used in stationary and mobile work machines.

The test bench was developed for the individual demands on performance testing of combined cooling power packs from scratch. It supplies the cooler to be tested with a defined volume flow of compressed air, coolant or hydraulic oil on the side to be cooled. The operating parameters of the media to be cooled are defined and automatically monitored and controlled; at the same time cooling air is led to the test specimen on the outer side – again with a predefined volume flow covering the performance range of various applications. The cooling performance can be calculated from the temperature drop of the specimens, external and internal pressure losses are also measured. Based on these features the new test bench allows to accurately adapt the cooler to the respective requirements specification. In addition it provides the engineers of KTR with starting points for the advanced development of the cooling technology and the focused performance rise with existing types of power packs. This capacity is particularly sought after since the increasing demands on exhaust quality require additional components for exhaust gas treatment.

The highly accurate measurement results the test bench provides allow us to better understand the overall system of »combined coolers« along with its components – which in turn enables us to work in the right direction when optimising. This applies, as an example, with regard to the comparison of heat exchangers with different combinations of lamellas, but also focused detail enhancement of other fluidic components. Consequently we are in a position to increase the efficiency of the coolers, for example by reducing pressure losses and improving the aerodynamics of the cooling airflow. We will make intensive use of these new options – both with customer projects and within the framework of research projects.

Contact

Joachim Grunwald

Head of Business Unit Coolers